High temperature bearings are critical components in machinery exposed to extreme heat, where standard bearings would rapidly degrade. Used across industries such as metallurgy, food processing, glass production, and aerospace, these bearings ensure reliable rotation even at 1000°C and beyond. This in-depth guide explains everything engineers, buyers, and maintenance teams need to know: from design principles and material science, to lubrication methods, application examples, failure prevention, and selection criteria.

1. What Are High Temperature Bearings?

High temperature bearings are a class of rolling bearings engineered to operate under sustained or cyclic high-heat environments, typically beyond 150°C (302°F), and up to 1000°C (1832°F) or more in specialized cases. They are designed to resist lubricant breakdown, material softening, dimensional distortion, and premature fatigue — all of which commonly occur with conventional bearings under thermal stress.

2. Key Characteristics of High Temperature Bearings

To meet the demands of high-heat environments, these bearings typically feature:

- Heat-resistant steel or ceramic construction for dimensional stability

- Specialized internal clearances to compensate for thermal expansion

- Dry lubricants such as graphite or MoS₂, or high-temp greases

- Minimal to zero maintenance during long-term operation

- Corrosion and oxidation resistance in humid or chemically aggressive atmospheres

3. Typical Operating Temperature Ranges

| Bearing Type | Material | Max Operating Temperature |

|---|---|---|

| Standard Chrome Steel (100Cr6) | Through-hardened steel | 120–180°C |

| Stainless Steel (440C, 630) | Martensitic or precipitation-hardening | 250–400°C |

| Hybrid Ceramic | Si₃N₄ balls + steel rings | 450–600°C |

| Full Ceramic (ZrO₂ / Si₃N₄) | All-ceramic | 600–1000°C+ |

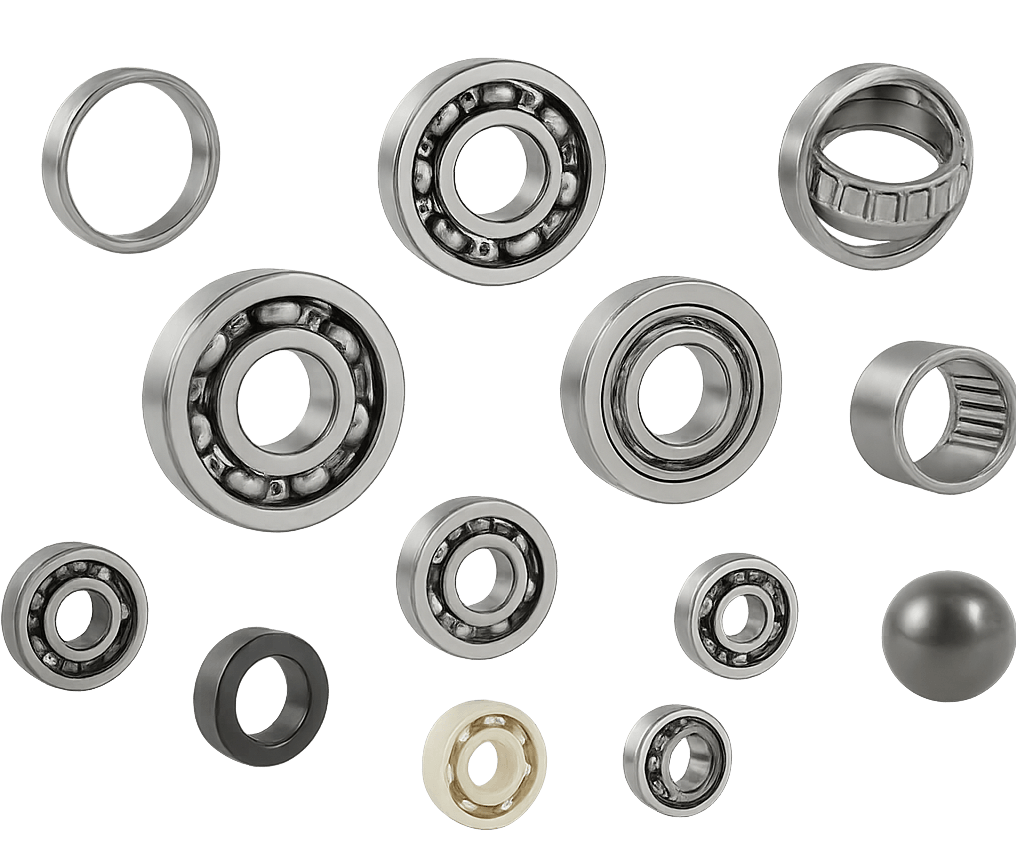

4. Common Types of High Temperature Bearings

The choice of bearing depends on load direction, rotational speed, and environmental conditions. Common variants include:

- Deep Groove Ball Bearings: Versatile, support radial and limited axial loads. Common in baking lines, electric motors, blowers.

- Angular Contact Ball Bearings: Handle combined loads, suited for high-speed spindles or compressors.

- Cylindrical Roller Bearings: For heavy radial loads in kilns, furnace rolls, and continuous casters.

- Tapered Roller Bearings: Handle both radial and axial loads. Used in hot rolling mills and gearboxes.

- Full Ceramic Bearings: Ideal for ultra-high temperatures or chemically aggressive media (e.g., acid vapor, vacuum ovens).

5. Material Selection: Pros and Cons

Choosing the right material is crucial for high temperature durability:

- Chrome Steel: Low cost, limited to 150–180°C. Not suitable for thermal cycling.

- Stainless Steel: Improved corrosion and oxidation resistance. Can handle short-term thermal spikes better.

- Hybrid Ceramic: Lightweight, low friction, handles temperature fluctuations. Cost-effective for high-speed, moderate-load settings.

- Full Ceramic: Non-conductive, lubricant-free, excellent in vacuum, radiation, or acidic atmospheres. Expensive, brittle under impact loads.

6. Lubrication Methods

Heat affects all lubrication strategies. High temperature bearing lubrication options include:

- Dry lubricants – Graphite, MoS₂, PTFE coatings; often used in open bearings above 300°C

- High-temp greases – Silicone, bentonite clay, PFPE greases rated 200–1000°C

- Solid lubricants – Impregnated cages, ceramic-polymer matrix coatings

- Lubrication-free bearings – Full ceramic or sealed-for-life options for inaccessible environments

7. Application Examples by Industry

High temperature bearings are not one-size-fits-all. Below are examples by sector:

- Metallurgy: Roller tables, billet transfer, furnace drives — require sealed or dry-lube roller bearings

- Food Processing: Ovens, rotisseries, dryers — demand FDA-approved greases or stainless full ceramic bearings

- Textile/Paper: Calenders, dryer cylinders — prefer open deep groove bearings with thermal clearances

- Automotive: Exhaust gas recirculation (EGR), turbochargers — require compact, hybrid angular contact designs

- Glass Manufacturing: Lehrs, float lines — use solid-lubricated cylindrical rollers with oxide-resistant coatings

- Aerospace: Turbines, cabin systems — rely on hybrid ceramics and high-speed grease-retention systems

8. Common Failure Modes (and How to Prevent Them)

High temperature bearings are durable — but not immune to failure. Typical causes include:

- Lubricant breakdown: Results in galling, scoring; use temperature-rated lubricants

- Thermal expansion mismatch: Can cause preloading or excessive play; select correct C3/C4 clearance

- Oxidation and corrosion: Especially in food/chemical lines; use stainless or coated bearings

- Contamination ingress: Seal failure under heat; consider labyrinth or shielded designs

- Improper installation: Overheating during mounting or lack of thermal compensation can lead to early failure

9. How to Choose the Right High Temperature Bearing

When selecting a high temperature bearing, consider:

- Temperature range: Identify both continuous and peak temperatures.

- Load type and magnitude: Radial, axial, shock load, or vibration sensitivity.

- Rotational speed: Higher speeds favor ceramic or hybrid solutions.

- Lubrication strategy: Determine if re-lubrication is possible or sealed-for-life is required.

- Environment: Humidity, dust, chemicals, vacuum, or food-grade compliance?

- Mounting and maintenance access: Choose sealed or self-lubricating designs for hard-to-reach locations.

10. Purchasing Tips & Cost Considerations

High temperature bearings are not commodity items — and the cheapest is rarely the best. For long-term value, consider:

- Life cycle cost (LCC), not just upfront price

- Supplier’s heat-resistance testing and material traceability

- OEM vs. generic: trusted brands offer proven designs and traceable quality control

- Custom designs: request modified clearance, special grease, or unique cage materials as needed

11. High Temperature Bearing Myths Debunked

- Myth: “All stainless bearings are high-temp” → Not true. AISI 304 or 440 may still fail above 300°C.

- Myth: “Dry bearings don’t need any maintenance” → Depends on load and cycle — periodic inspection is still required.

- Myth: “High-temp means low speed” → Ceramic hybrids allow high RPM in hot environments.

12. Conclusion

High temperature bearings are specialized components engineered for reliability under heat, stress, and challenging environments. A proper understanding of material science, lubrication options, load factors, and environmental challenges is essential to choose the right bearing and ensure operational success.

Whether you’re designing for a food-grade baking oven or a steel mill’s furnace line, choosing the correct high temperature bearing is critical. For technical consultation or OEM customization, contact our team of bearing engineers today.