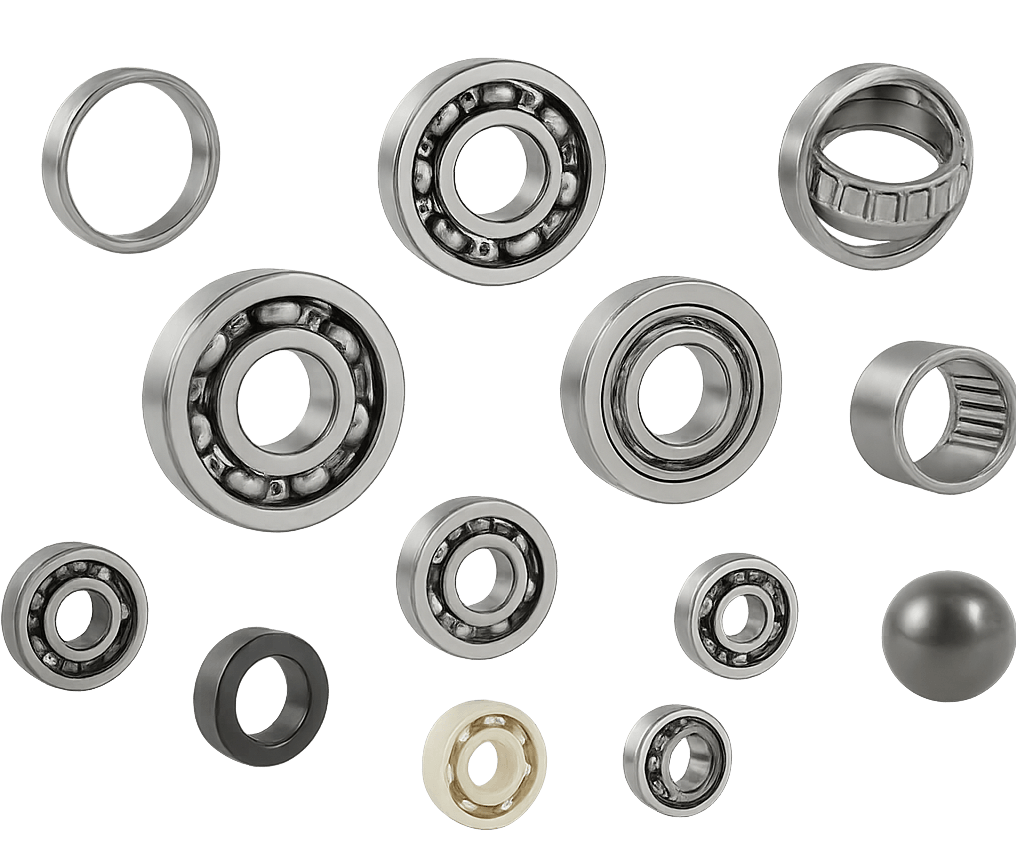

When operating in extreme heat, standard bearings often fail, leading to unplanned downtime and costly repairs. High temperature bearings are specifically engineered to withstand elevated temperatures while maintaining performance and durability. This article provides a comprehensive overview of high temperature bearings, including their design features, lubrication solutions, material selection, common failure modes, industry applications, and key purchasing considerations. Whether you are a maintenance engineer, plant manager, or procurement specialist, this guide will help you make informed decisions and reduce operating costs.

Why High Temperature Bearings Are Essential

In industrial environments where temperatures exceed 150°C—and in some cases up to 1600°C—using the right bearing technology is critical. Standard bearings experience lubricant breakdown, material fatigue, and premature failure under such conditions. This leads to costly equipment downtime, unscheduled maintenance, and safety risks.

Industries That Rely on High Temperature Bearings

- Metal Processing: Continuous casting machines, blast furnaces, and annealing furnaces.

- Food & Beverage: Industrial ovens, coffee roasting equipment, and baking lines.

- Furnaces & Kilns: Ceramic, cement, and glass production kilns operating above 300°C.

- Power Generation: Gas and steam turbines, generator cooling systems.

- Chemical & Environmental: Paint drying ovens, incinerators, ash handling systems.

Risks of Using Standard Bearings in High-Heat Applications

- Lubricant Breakdown: Conventional greases degrade above 120–150°C, leading to increased friction and wear.

- Seal Failure: Standard seals harden, crack, or leak under extreme heat, exposing bearings to contaminants.

- Cage Deformation: Nylon or polymer cages may melt or weaken at high temperatures, risking misalignment and seizure.

- Material Fatigue: Thermal expansion and repeated heating/cooling cycles cause steel fatigue, reducing load capacity and service life.

Key Design Features of High Temperature Bearings

Material Options

| Type | Temperature Range | Advantages | Applications |

|---|---|---|---|

| Heat-Stabilized Steels | Up to 500°C | Cost-effective, good load capacity | Steel processing, kilns |

| Hybrid Bearings | 150–220°C | Lower friction, longer life vs. steel-only bearings | High-speed machinery |

| Full Ceramic Bearings | Up to 1600°C | Extreme heat and corrosion resistance, minimal lubrication needs | Furnaces, aerospace, vacuum environments |

Thermal Expansion Management

- Bearings use increased internal clearances (C3, C4, C5) to accommodate thermal growth and prevent seizure.

- Special coatings like phosphate layers reduce metal-to-metal contact and improve lubricant retention at high temperatures.

Lubrication Solutions for High Temperature Bearings

Grease Options (Up to ~260°C)

- Silicone-based greases

- PFPE (Perfluoropolyether) greases

- High-temp polyurea greases

Solid Lubricants (Dry Lubrication for 300°C+)

- Graphite: Up to 500°C (air), higher in inert atmospheres

- Molybdenum Disulfide (MoS₂): Up to 400°C

- Hexagonal Boron Nitride: Up to 1000°C

- Calcium Fluoride: Up to 1300°C

Solid lubricants minimize maintenance needs and are ideal for applications where relubrication is difficult or impossible.

Operating Best Practices

Temperature Monitoring

- Install temperature sensors (e.g., thermocouples, infrared monitors) for real-time monitoring and alerts.

- Regularly inspect bearings using infrared thermometers during maintenance rounds.

Load and Speed Management

- Design systems to operate near their efficiency sweet spot to minimize stress on bearings.

- Ensure correct shaft alignment and proper housing fits to avoid additional loads from thermal distortion.

Installation and Maintenance Tips

- Follow manufacturer guidelines for mounting procedures.

- Avoid over-lubrication and mixing lubricant types.

- Schedule periodic alignment checks and vibration analysis.

Steel vs. Hybrid vs. Ceramic Bearings: Performance Comparison

| Bearing Type | Max Temp | Load Capacity | Speed Capability | Maintenance Frequency |

|---|---|---|---|---|

| Steel Bearings | ~500°C | High | Moderate | Frequent |

| Hybrid Bearings | ~220°C | Moderate | High | Moderate |

| Ceramic Bearings | ~1600°C | Moderate | Very High | Low (often lifetime lubricated) |

Cost vs. Performance Considerations

While ceramic bearings have the highest upfront cost, their extended lifespan and reduced maintenance needs often result in the lowest total cost of ownership over time. Hybrid bearings offer a mid-range solution, while heat-stabilized steel bearings provide an economical choice for moderate temperatures.

Real-World Case Study

A steel manufacturing plant operating at ~350°C saw frequent failures with conventional steel bearings, causing production delays and repair costs. After switching to full ceramic high temperature bearings, the plant reported a 70% reduction in downtime and a 40% decrease in annual maintenance costs. This case highlights the long-term ROI of investing in the right bearing technology for high heat environments.

Common Troubleshooting Tips

| Problem | Likely Cause | Solution |

|---|---|---|

| Unexpected Overheating | Inadequate lubrication, overload, misalignment | Check lubrication, realign shafts, review load specs |

| Excessive Noise | Debris, poor lubrication, cage damage | Clean, re-lubricate, inspect for component damage |

| Vibration | Imbalance, mounting errors | Rebalance machinery, ensure correct installation |

| Seal Failure | Excessive temperature or chemical attack | Upgrade to high-temp seal materials (e.g., Viton, silicone) |

Conclusion

Selecting the right high temperature bearing for your application is critical for minimizing downtime, improving operational efficiency, and reducing maintenance costs. Consider factors like temperature range, load, speed, lubrication, and material compatibility when making your selection.

Contact BearingMaker for expert support in choosing the right high temperature bearings and lubrication solutions for your specific needs.