Ball bearings may be small, but they are vital to the performance and longevity of countless machines across modern industries. These precision components reduce friction and support both radial and axial loads, enabling smooth and efficient rotation. But how exactly are ball bearings made? What materials are used? And how do manufacturers ensure their quality?

In this article, we’ll walk through the entire manufacturing process of ball bearings, explore their key components, delve into quality control procedures, and highlight the industries that rely on them every day.

What Are Ball Bearings?

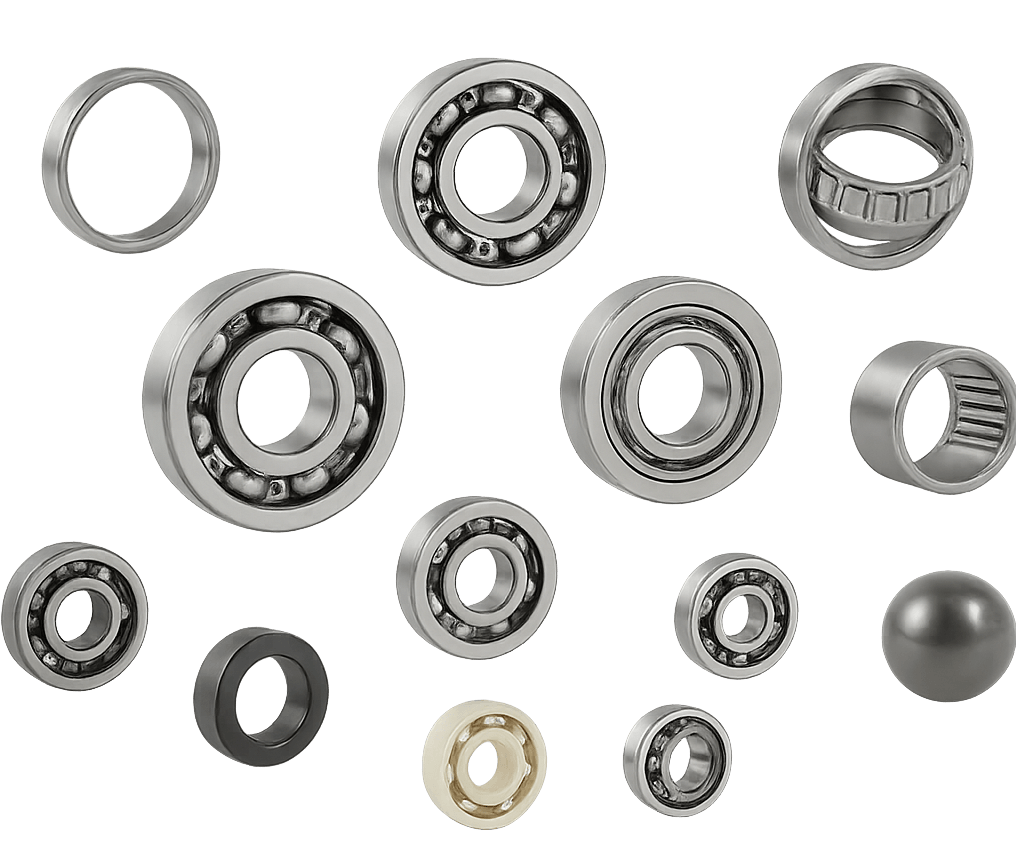

Ball bearings are rolling element bearings that use balls to maintain the separation between the bearing races. Their primary function is to reduce rotational friction while supporting loads. A typical ball bearing includes the following parts:

-

Inner Ring (Race): Fits around the shaft and provides a raceway for the balls.

-

Outer Ring (Race): Houses the balls and fits into the bearing housing.

-

Balls: Hardened spherical elements that roll between the rings, carrying the load.

-

Cage (Retainer): Keeps the balls evenly spaced and prevents contact between them.

-

Shields/Seals: Protect against contaminants like dust, moisture, and debris.

Each of these components must be manufactured with extreme precision to ensure performance, reliability, and longevity.

The Ball Bearing Manufacturing Process

The process of making ball bearings is highly specialized and involves multiple precise steps:

1. Material Selection

Most ball bearings are made from high carbon chromium steel (e.g., SAE 52100) due to its wear resistance and hardness.

Other materials include stainless steel (for corrosion resistance), ceramics (for high-speed or high-temperature applications), and polymers (in lightweight or low-load applications).

2. Forming the Components

-

Forging: Steel is heated and forged into rings to align the grain structure, increasing strength and fatigue life.

-

Casting: Used occasionally for complex or large parts; molten metal is poured into molds to form the desired shapes.

3. Heat Treatment

Forged parts are hardened using a combination of quenching and tempering.

The goal is to achieve an optimal balance of hardness (for wear resistance) and toughness (to prevent cracking under load).

4. Precision Machining and Grinding

-

Inner and outer rings are machined using CNC turning, milling, and drilling.

-

Balls are ground to near-perfect sphericity using fine grinding and lapping.

-

Tolerances are typically within microns, ensuring precise fit and low vibration.

5. Assembly and Lubrication

-

Components are cleaned, then assembled with the proper number of balls placed between the rings and secured by the cage.

-

Lubrication—either oil or grease—is applied to reduce friction and wear.

-

Depending on the application, seals or shields may be installed.

Quality Control and Inspection

Ball bearings undergo extensive quality assurance before leaving the factory. Common tests include:

-

Visual Inspection: Checking for surface defects or assembly errors.

-

Dimensional Accuracy: Measuring bore diameter, outer diameter, width, and ball size with high-precision tools.

-

Roundness and Runout: Verifying that components are concentric and within circularity tolerances.

-

Surface Roughness: Measured using profilometers to ensure smooth contact surfaces.

-

Hardness Testing: Conducted using Rockwell or Vickers scales.

-

Noise and Vibration Analysis: Identifying abnormal vibration or acoustic emissions using advanced testing rigs.

-

Lubricant Analysis: Checking for contamination, oxidation, and viscosity consistency.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle inspection help identify subsurface defects.

-

Performance Testing: Bearings are run under real-world load, speed, and temperature conditions to test endurance and fatigue life.

These quality checks ensure each bearing meets ISO standards and specific customer requirements.

Applications of Ball Bearings

Ball bearings are used in virtually every industry. Here are some key sectors:

-

Automotive: Engines, gearboxes, wheel hubs, air conditioning compressors.

-

Aerospace: Jet engines, landing gear, flight control systems.

-

Industrial Equipment: Motors, pumps, gearboxes, conveyor systems.

-

Consumer Electronics: Fans, hard drives, electric tools.

-

Agriculture & Renewable Energy: Wind turbines, tractors, and harvesters.