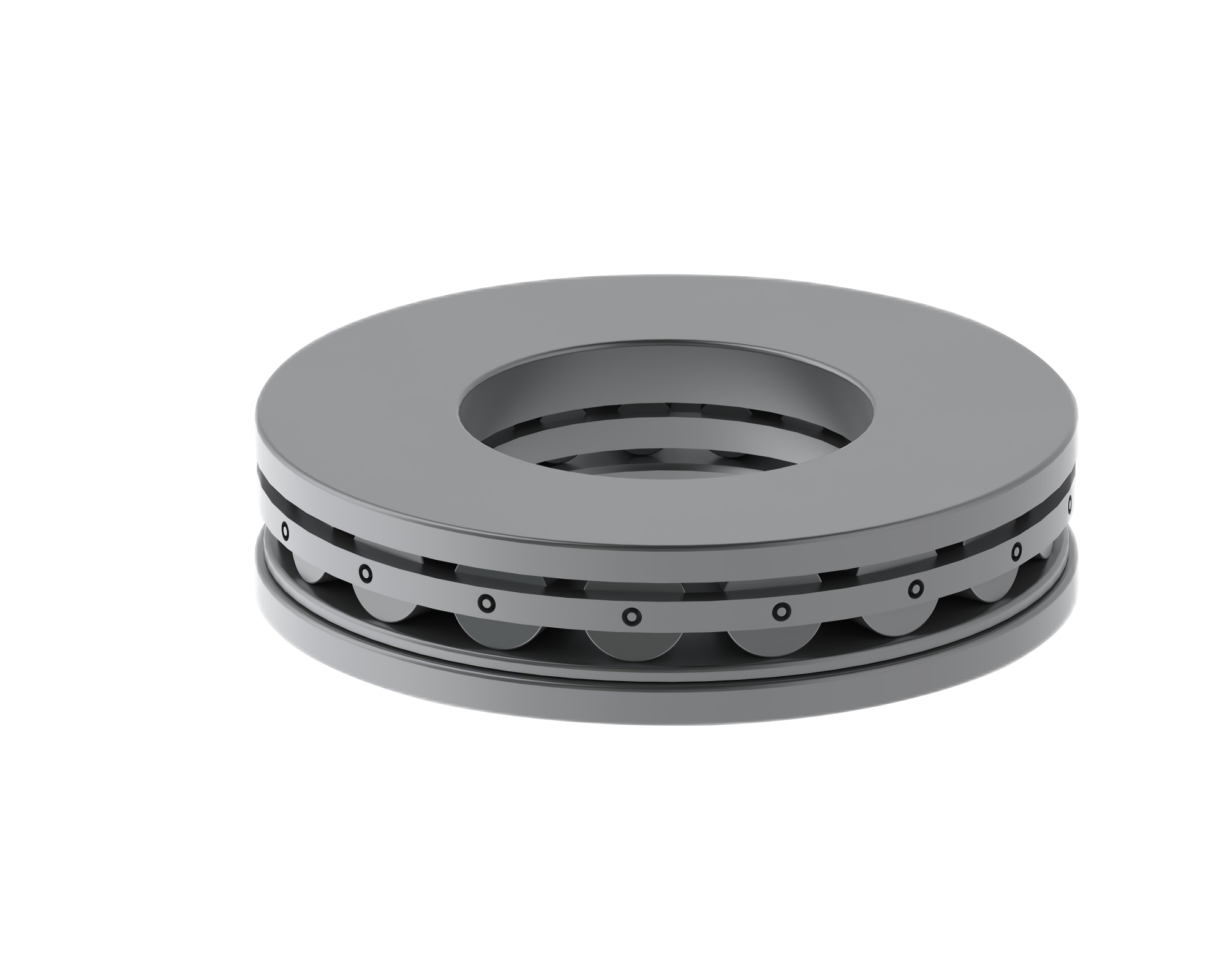

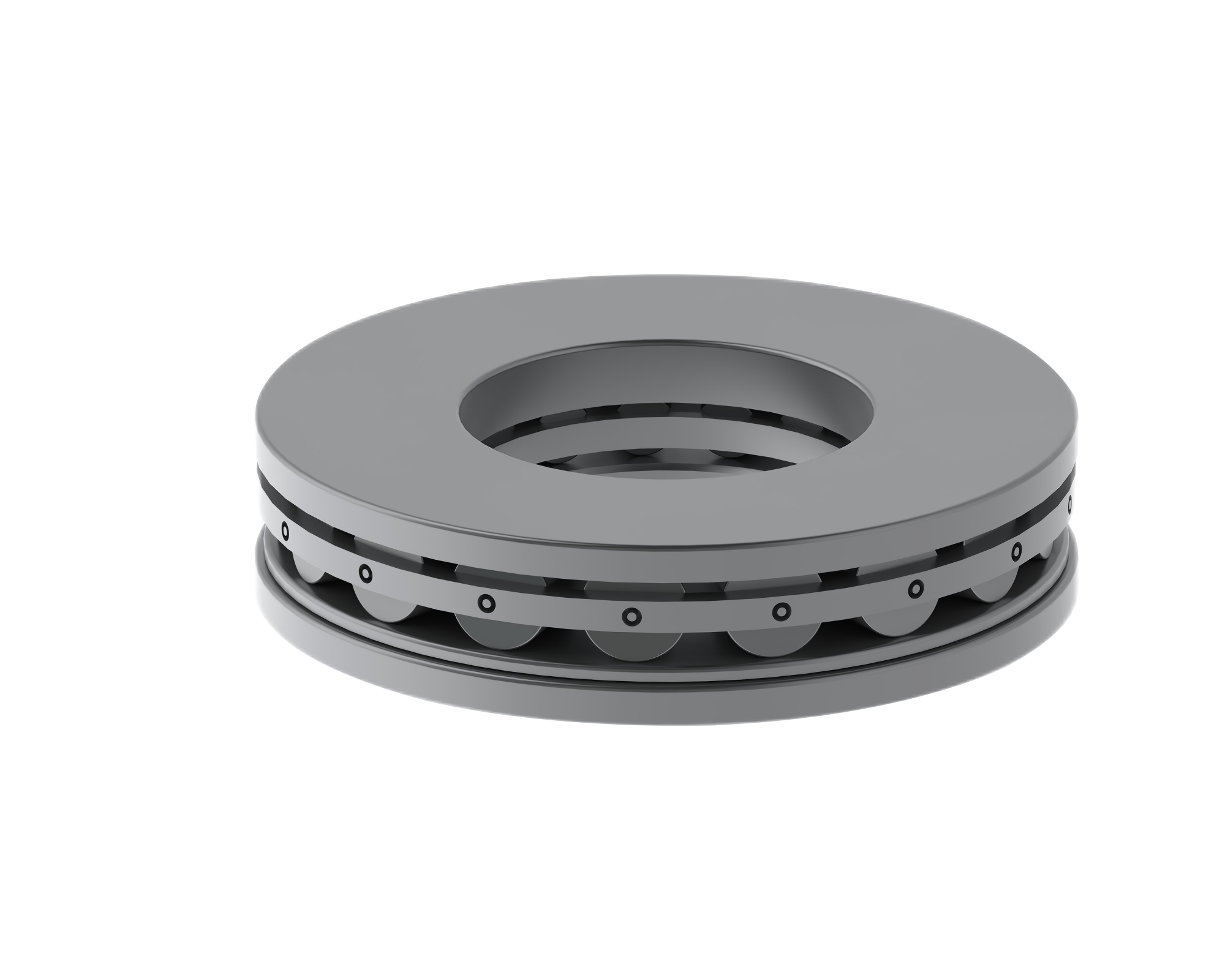

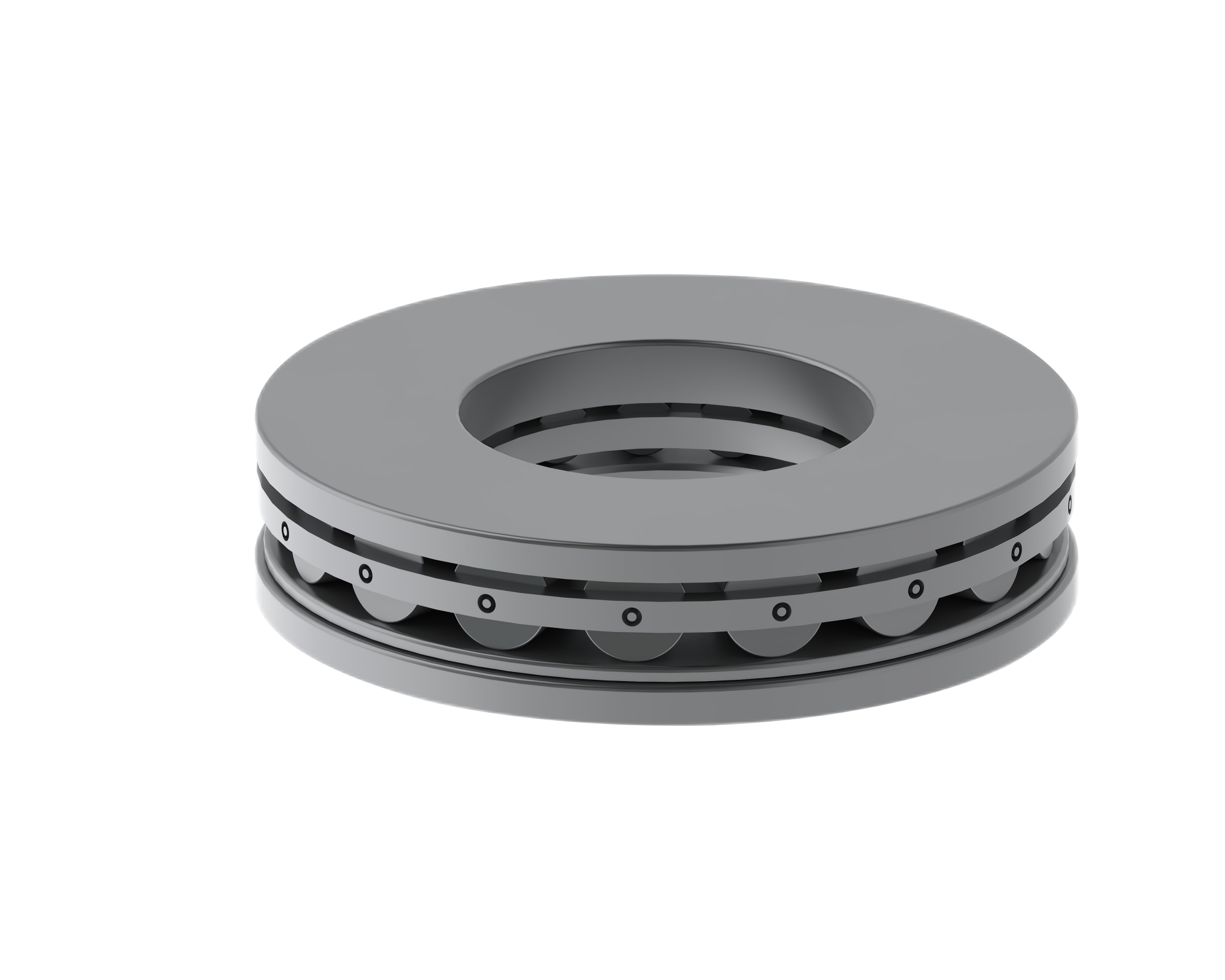

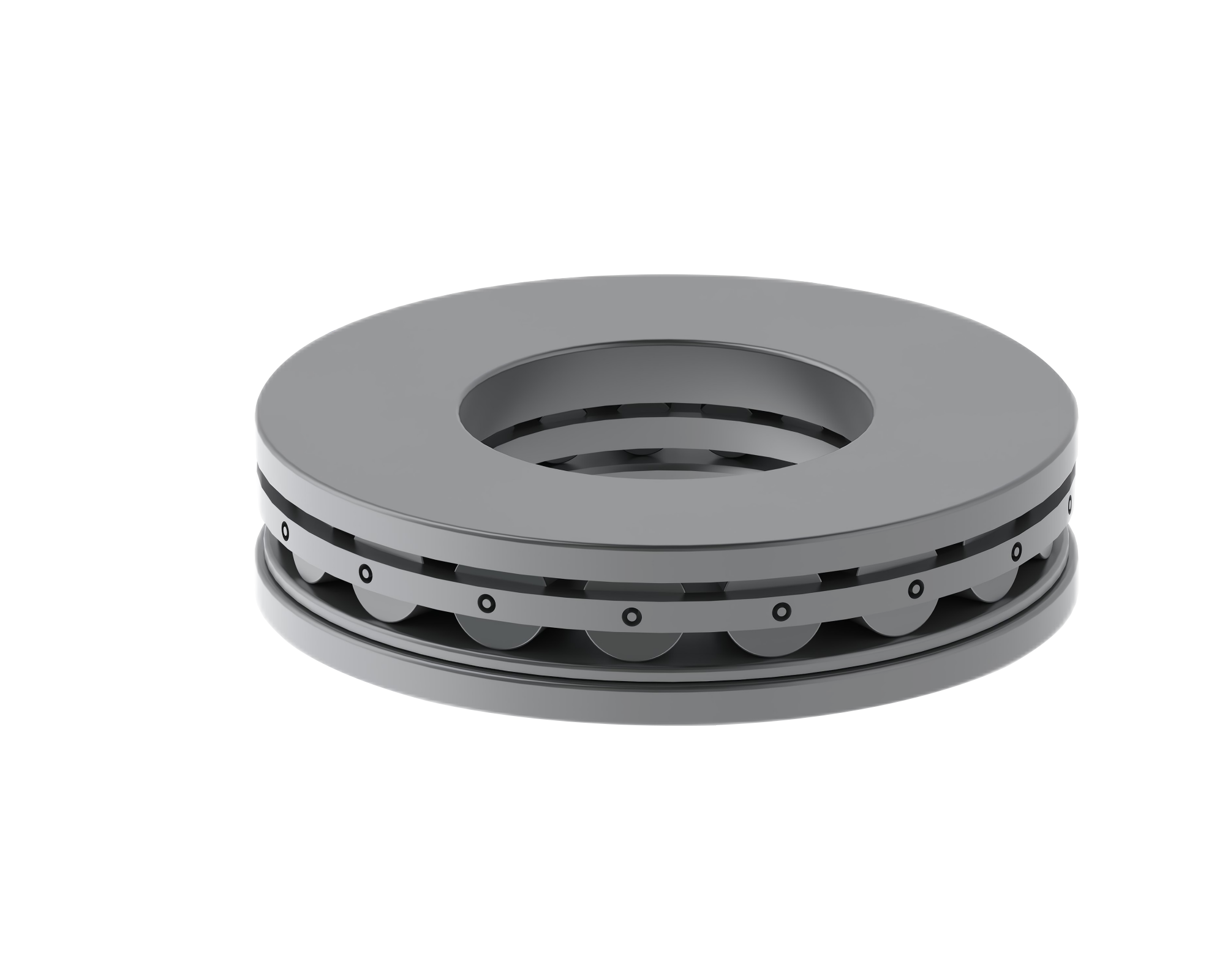

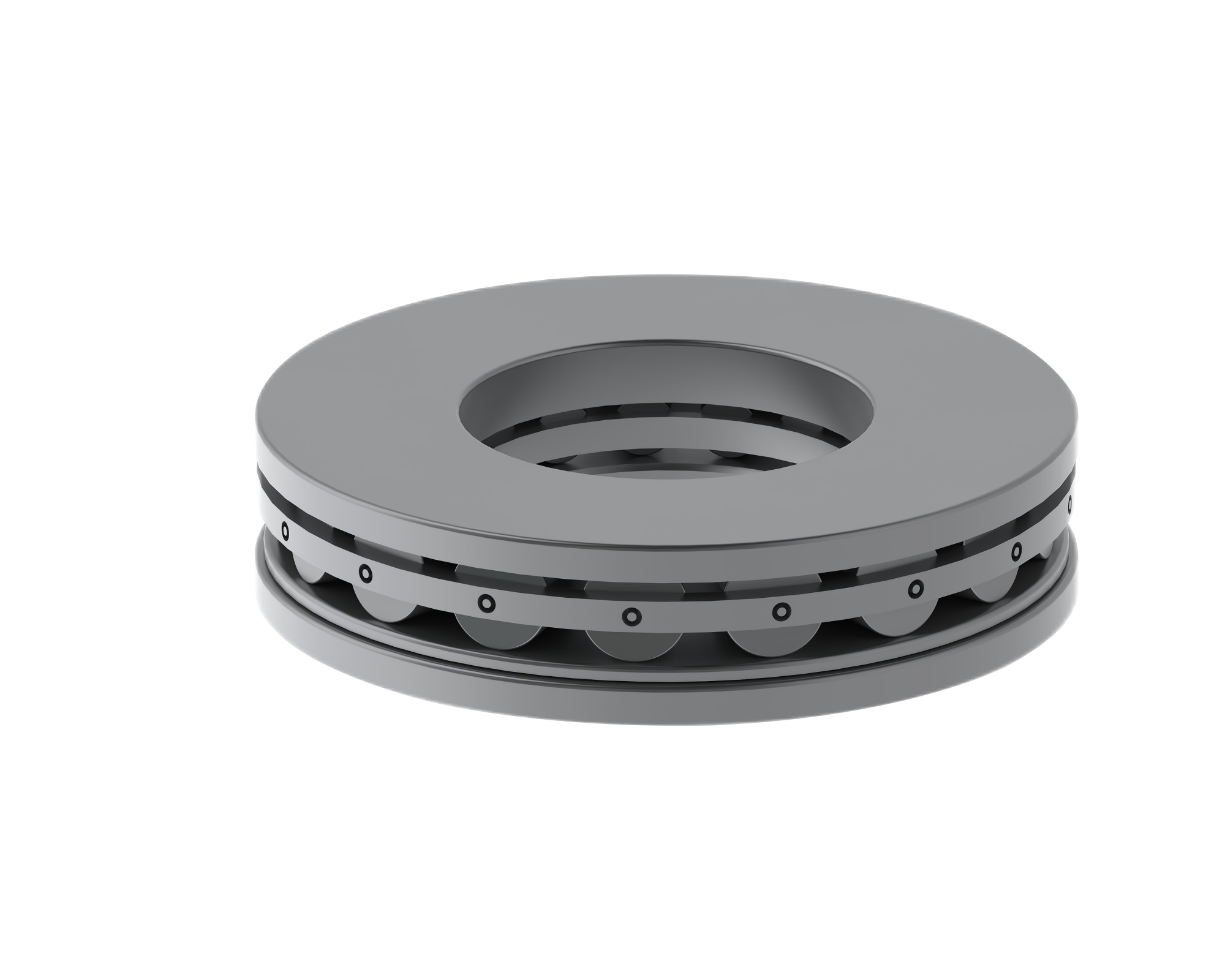

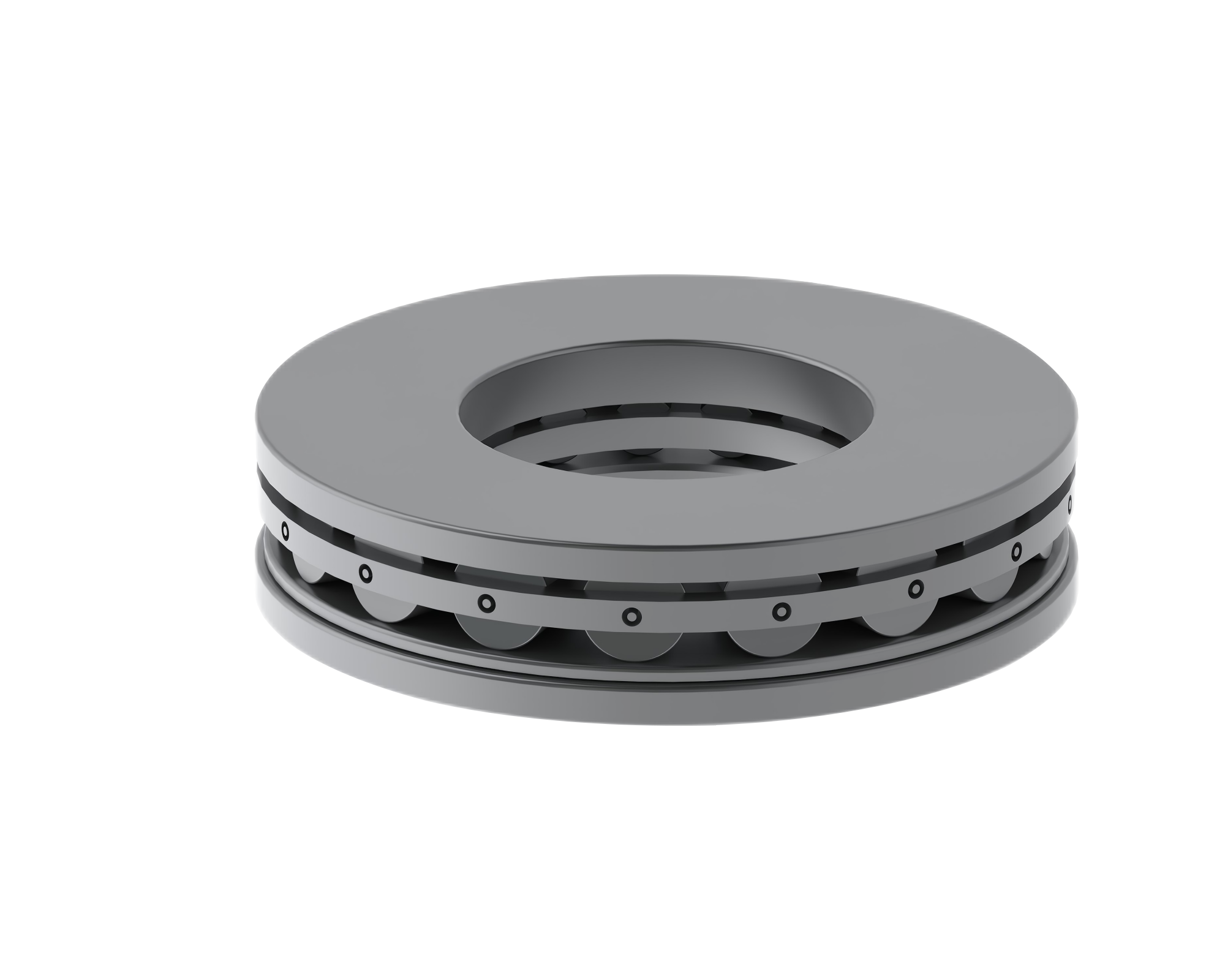

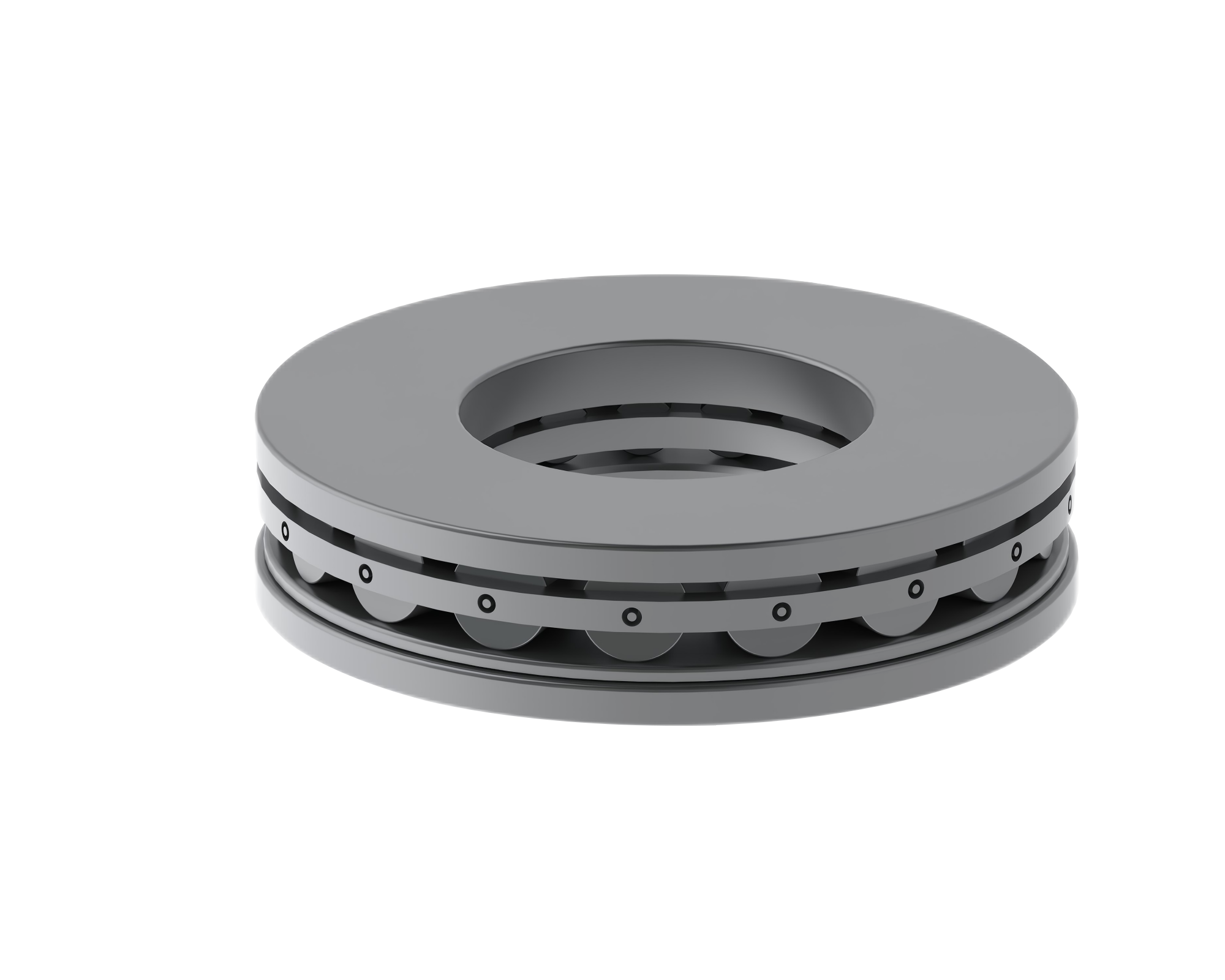

B-8750-G

Design Features of B-8750-G Bearing

B-8750-G is designed to provide enhanced load-bearing capacity and durability in high-stress environments. B-8750-G outer dia is 26″. Its bore dia is 14″. Its advanced materials and precision engineering minimize friction and wear, ensuring long-term, reliable performance.

What Benefits Can B-8750-G Bearing Provide?

- Enhanced Load Capacity: Engineered to handle higher loads, making it ideal for applications with demanding load requirements.

- Reduced Friction and Wear: Precision design and advanced materials minimize friction, reducing wear and extending the bearing’s lifespan.

- Improved Efficiency: Its design allows for smoother operation, which improves overall system efficiency and can lead to energy savings.

- High Durability: Resistant to wear and tear even in high-stress environments, resulting in less frequent replacements and lower maintenance costs.

- Reliable Performance: Provides consistent performance, which contributes to improved safety and stability in various applications.

What Can B-8750-G Bearing Be Used for?

- Heavy Machinery: Ideal for construction and industrial equipment that requires high load-bearing capabilities and durability, such as excavators, cranes, and loaders.

- Automotive and Transportation: Suitable for vehicles and rail systems, where it supports stability and reduces wear in high-load areas, including wheel hubs and transmission systems.

- Aerospace Applications: Used in aircraft systems to handle heavy loads with precision, ensuring high performance and reliability in challenging environments.

- Renewable Energy: Useful in wind turbines and solar tracking systems where it aids in withstanding environmental stresses and rotating loads over long periods.

- Manufacturing Equipment: Supports conveyor belts, robotic arms, and other machinery by minimizing friction and improving efficiency in high-use environments.