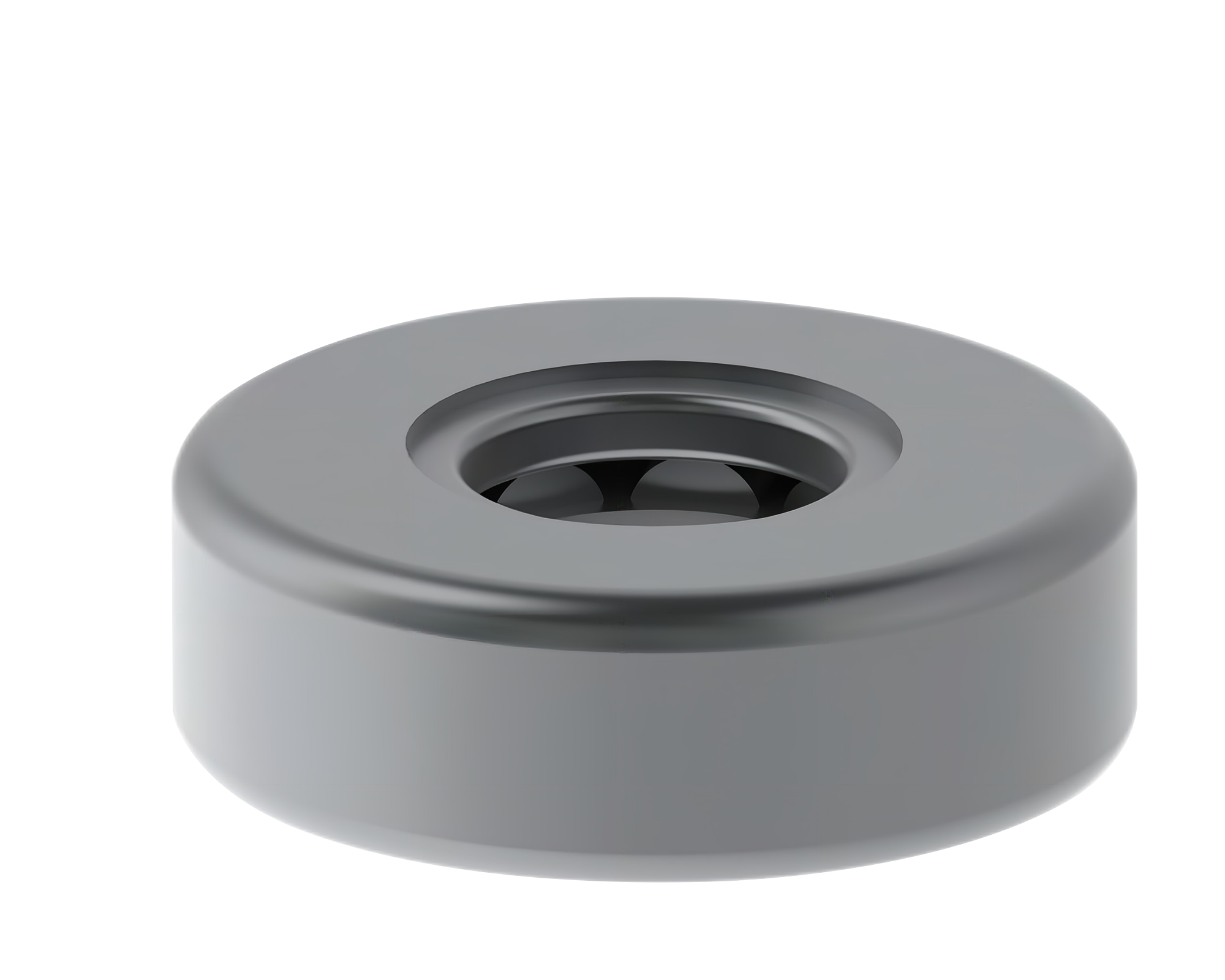

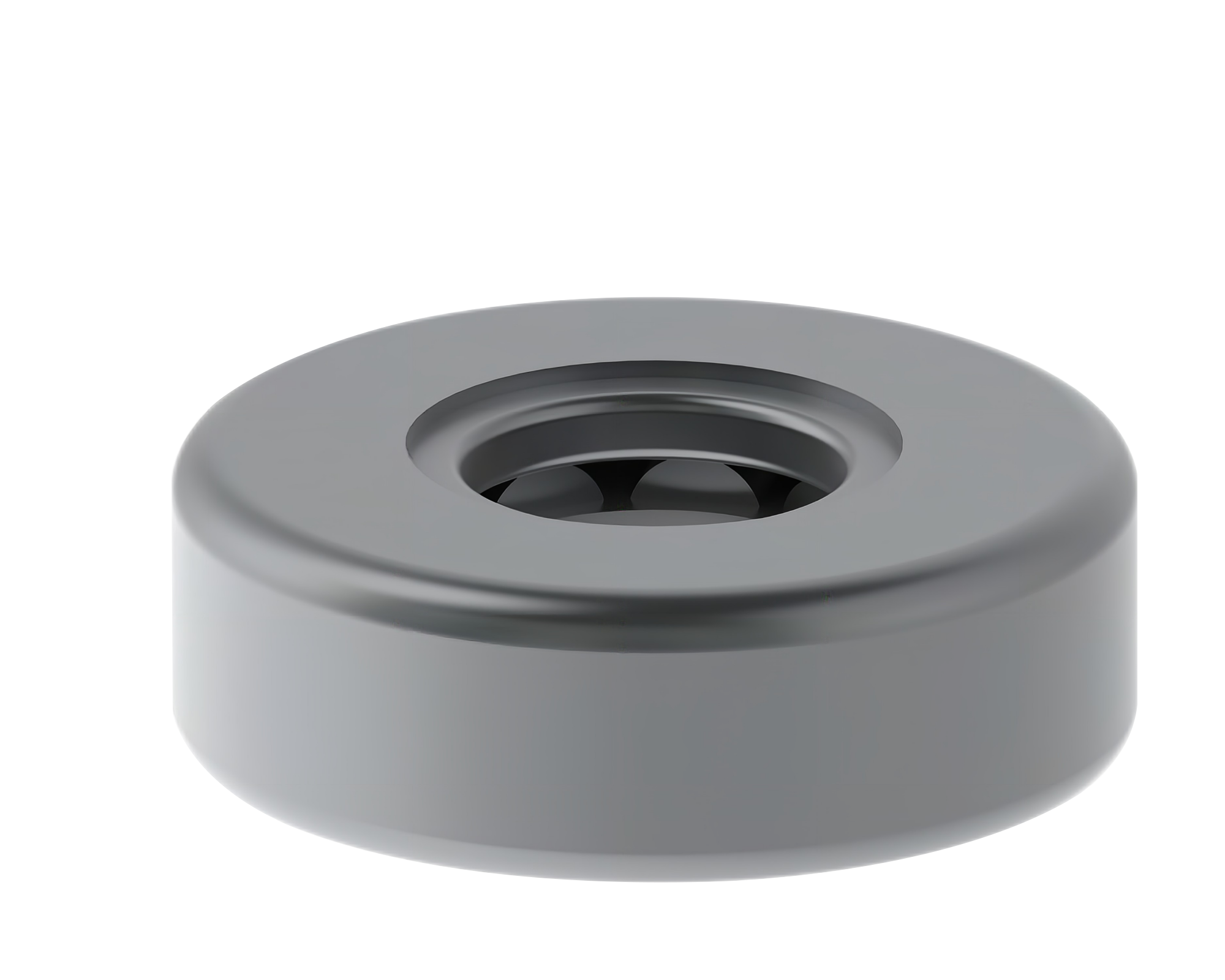

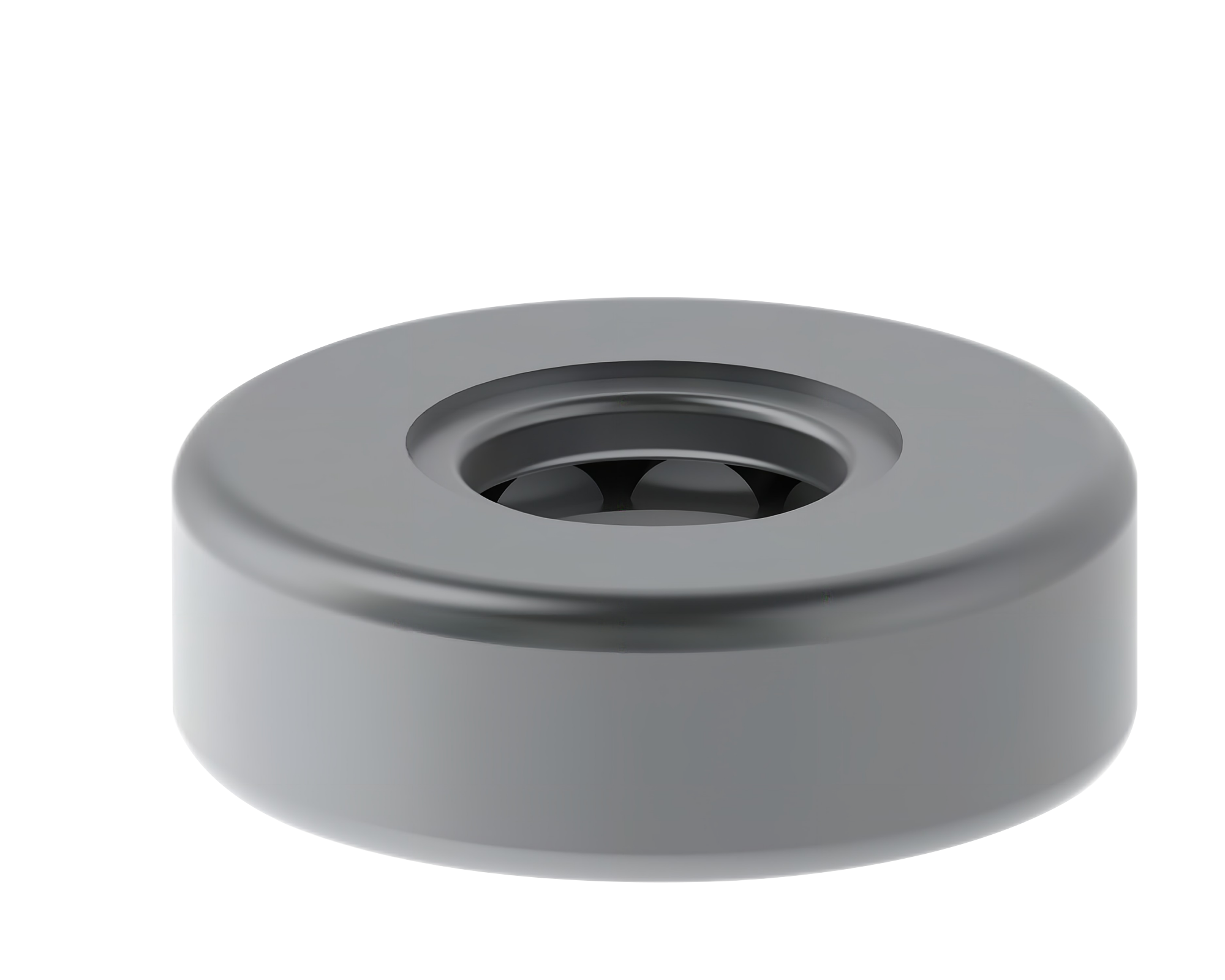

T94W-904A4

Design Features of T94W-904A4 Bearing

T94W-904A4 is designed with a high-precision structure to enhance stability and accuracy in motion-intensive applications. T94W-904A4 outer dia is 1.8906″. Its bore dia is 0.947″. Its robust materials and optimized design reduce wear, extending the lifespan and reliability of the component.

What Benefits Can T94W-904A4 Bearing Provide?

- High Precision: Designed for accuracy in motion control, which enhances the overall stability of machinery and reduces alignment issues.

- Extended Lifespan: Made with durable materials that resist wear and tear, resulting in a longer operational life and lower maintenance needs.

- Reduced Friction: The optimized design minimizes friction, promoting smoother movement and improved efficiency in applications.

- Enhanced Load Capacity: Built to handle significant loads, making it suitable for heavy-duty and high-performance applications.

- Consistent Performance: Delivers reliable performance even in demanding environments, reducing downtime and improving system efficiency.

What Can T94W-904A4 Bearing Be Used for?

- Industrial Robotics: Ideal for robotic arms and automated machinery requiring high precision and smooth, controlled movement.

- Medical Equipment: Useful in imaging systems and surgical devices where stability and low-friction performance are essential.

- Semiconductor Manufacturing: Perfect for precision equipment in semiconductor fabrication, where accurate positioning and reliability are critical.

- Aerospace Systems: Employed in aircraft components, such as control surfaces and landing gear, to ensure durability and smooth operation under stress.

- Automotive Components: Applied in suspension systems, transmission systems, and other areas that require high load capacity and stable motion.