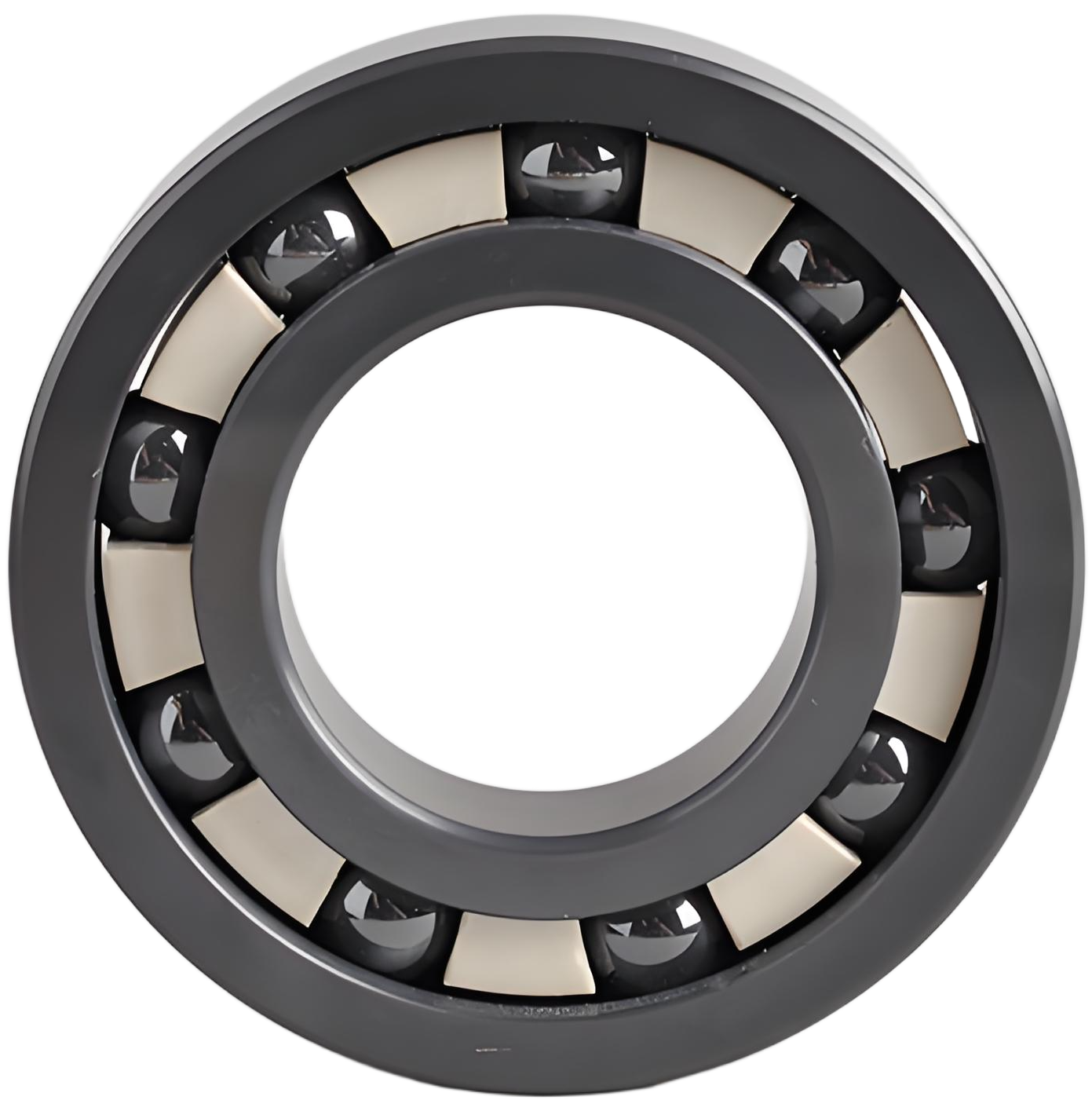

1602 Ceramic Bearings

Design Features of 1602 Ceramic Bearings

1602 Ceramic Bearings are precision bearings designed with balls made from advanced ceramic materials, including Silicon Nitride (Si3N4), Zirconia (ZrO2), or Silicon Carbide (SiC). They have a bore diameter of 0.25″, an outer diameter of 0.6875″, and a width of 0.25″. These bearings offer superior performance in terms of resistance to heat, corrosion, and wear, making them ideal for specific applications where these properties are crucial.

What Benefits Can 1602 Ceramic Bearings Provide?

- High-Temperature Resistance: Made from silicon nitride, these bearings withstand extreme temperatures, maintaining performance even in heat-intensive applications.

- Corrosion and Chemical Resistance: These bearings remain durable in environments exposed to corrosive chemicals.

- Low Friction: Reduced friction results in minimal wear, less heat generation, and an extended operational lifespan.

- Non-Magnetic: As ceramic, they are inherently non-magnetic, making them ideal for applications where magnetic interference is a concern.

- Electrical Insulation: Being non-conductive, they are perfect for applications requiring electrical insulation.

What Can 1602 Ceramic Bearings Be Used for?

These bearings excel in unique applications due to their specific properties:

- Precision Machine Tools: Especially in high-speed spindle applications where precision and reduced friction are crucial.

- Electric Motors: Ideal for high-efficiency, high-performance settings. Their non-conductive nature ensures minimal electrical interference.

- Aerospace Equipment: Used in systems sensitive to weight and extreme conditions, like satellite gyroscopes and guidance systems.

- Medical Devices: In high-performance equipment like MRI machines, surgical instruments, and dental drills, where precision and reduced noise are essential.

- High-Performance Vehicles: They handle high speeds with reduced heat production, making them ideal for wheel and engine bearings in race cars or motorcycles.