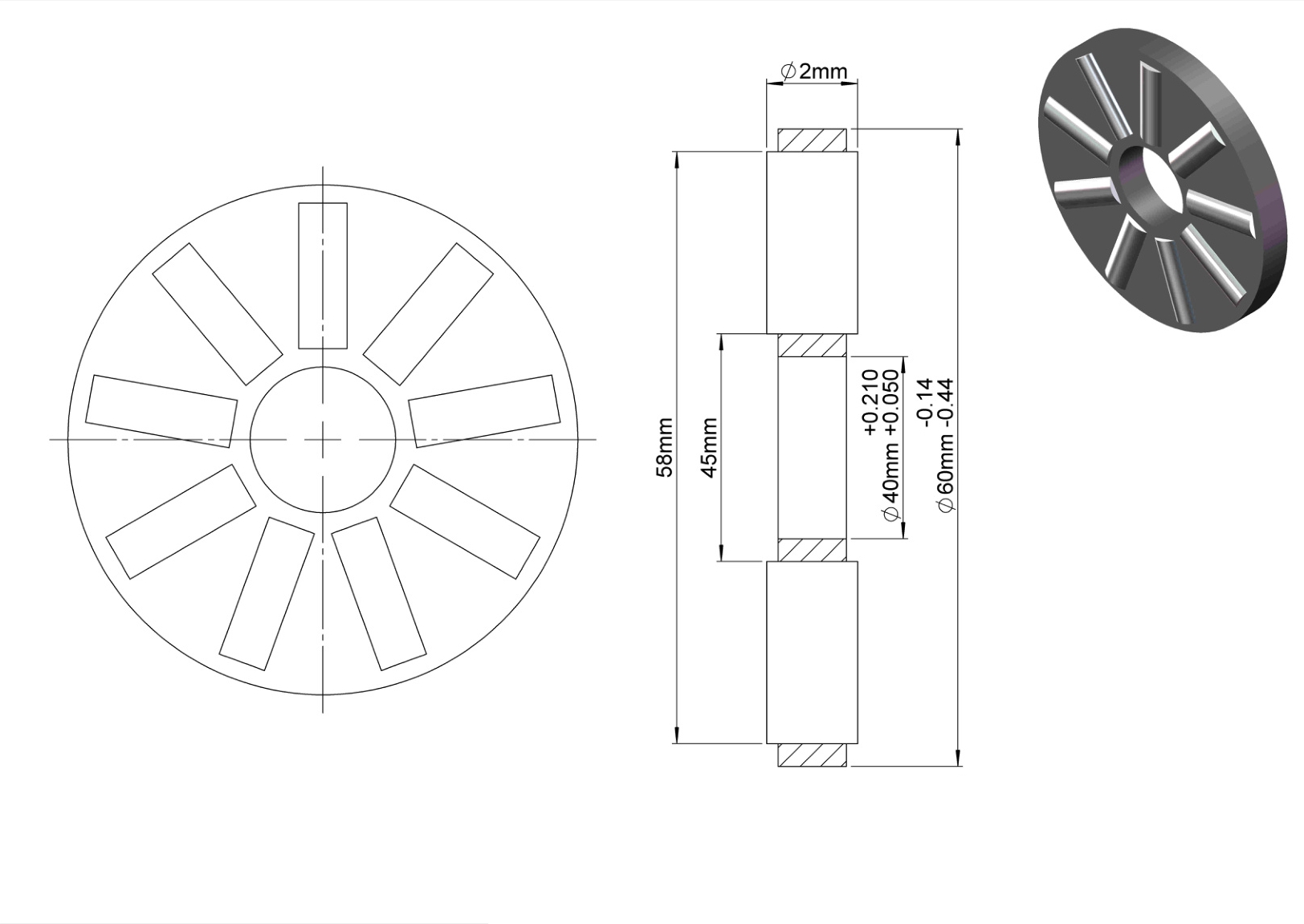

AXK4060

Design Features of AXK4060

AXK4060 features a structured design that holds a needle roller in place, ensuring even spacing and reducing friction for high load capacity. AXK4060 outer dia is 60 mm. Its bore dia is 40 mm. Typically thin and made from materials like steel or plastic, this cage allows for better lubrication distribution and is precision-engineered for smooth operation in compact applications.

What Benefits Can AXK4060 Provide?

- Reduced Friction: The cage maintains even spacing between needle rollers, minimizing contact and friction, which enhances efficiency.

- Improved Load Distribution: It ensures uniform load distribution across the needle rollers, increasing the bearing’s load capacity.

- Enhanced Durability: The cage helps protect the needle rollers from misalignment and wear, extending the bearing’s lifespan.

- Compact Design: Its thin profile allows for use in tight spaces while supporting high axial loads.

- Better Required: The cage design facilitates effective lubrication, reducing maintenance needs and improving performance.

- Stability: It prevents the needle rollers from skewing, ensuring stable operation under varying loads.

What Can AXK4060 Be Used for?

- Automotive Transmissions: To support gears and handle axial loads in compact spaces.

- Industrial Equipment: In machines that require efficient load handling and smooth axial movement.

- Aerospace Components: For lightweight applications needing high performance and reliability.

- Construction Machinery: In pivot points and other load-bearing assemblies.

- Power Tools: To reduce friction and wear in rotating components.