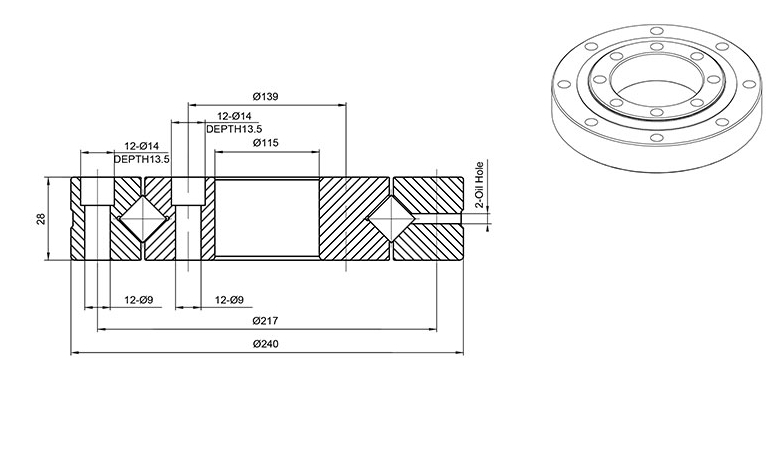

CRBFV11528ATUU

Design Features of CRBFV11528ATUU

CRBFV11528ATUU features a compact design with crossed rollers arranged at right angles, ensuring smooth and stable rotation. CRBFV11528ATUU outer dia is 240 mm. Its bore dia is 115 mm. This design allows it to handle complex loads, including radial, axial, and moment loads, while maintaining high accuracy and rigidity in applications.

What Benefits Can CRBFV11528ATUU Provide?

- High Load Capacity: It can handle radial, axial, and moment loads simultaneously, making it versatile for various applications.

- Compact Design: Its thin profile allows for space-saving installation while still maintaining strength and rigidity.

- High Precision: The crossed roller arrangement ensures smooth rotation with minimal deflection, providing excellent accuracy.

- Stable Operation: It maintains stability even under complex load conditions, enhancing reliability in demanding environments.

- Reduced Maintenance: With durable construction, it offers long service life, reducing the need for frequent replacements or repairs.

What Can CRBFV11528ATUU Be Used for?

- Industrial Robots: For joints and rotating components that require smooth and accurate movement.

- Machining Centers: In turntables and spindles, where high precision and load capacity are essential.

- Medical Equipment: Such as MRI machines and CT scanners, where precise positioning is crucial.

- Semiconductor Manufacturing: In wafer-handling systems and inspection devices for accurate and stable movement.

- Aerospace Applications: For components like radar systems and satellite positioning mechanisms that require reliable performance under complex loads.