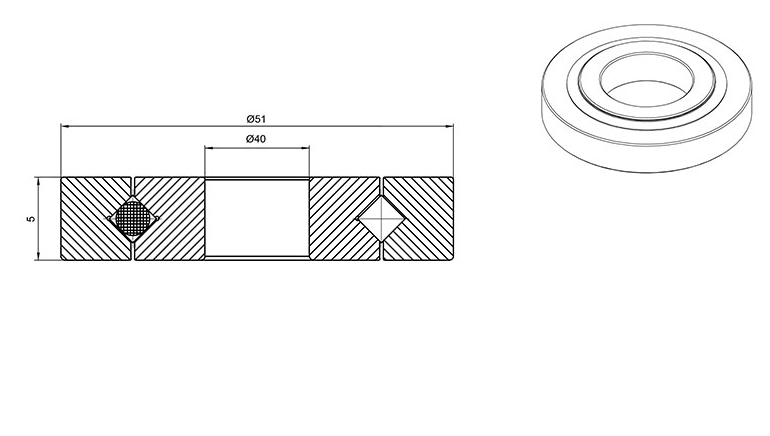

CRBT405A

Design Features of CRBT405A Bearing

CRBT405A is designed with a thin profile and high rigidity, making it ideal for compact applications that require precise motion. CRBT405A outer dia is 51 mm. Its bore dia is 40 mm. Its crossed roller arrangement allows it to withstand radial, axial, and moment loads simultaneously, ensuring smooth and stable performance in limited spaces.

What Benefits Can CRBT405A Bearing Provide?

- Space-saving design: Its ultra-thin profile allows for compact installations, making it ideal for applications where space is limited.

- High load capacity: Despite its slim size, it can support radial, axial, and moment loads simultaneously, offering excellent stability.

- Smooth, precise movement: The crossed roller arrangement ensures minimal friction and high rotational accuracy, improving overall performance.

- High rigidity: Its design offers enhanced stiffness, making it suitable for applications that require precise positioning and stable motion control.

- Versatile applications: It is commonly used in robotics, medical devices, and precision equipment where both high performance and space optimization are critical.

What Can CRBT405A Bearing Be Used for?

- Robotics: It provides precise positioning and smooth motion in robotic arms and joints, where space is limited.

- Medical devices: Used in medical equipment like MRI machines and surgical robots, where both high accuracy and compact design are essential.

- Semiconductor manufacturing: Offers precise movement control in wafer-handling systems and inspection equipment.

- Optical and measurement instruments: Ensures stable and accurate rotation in devices such as cameras, telescopes, and measuring equipment.

- Aerospace and defense: Ideal for use in lightweight, high-performance systems such as satellite positioning mechanisms and precision targeting devices.