D/W ER1038

Design Features of D/W ER1038 Bearing

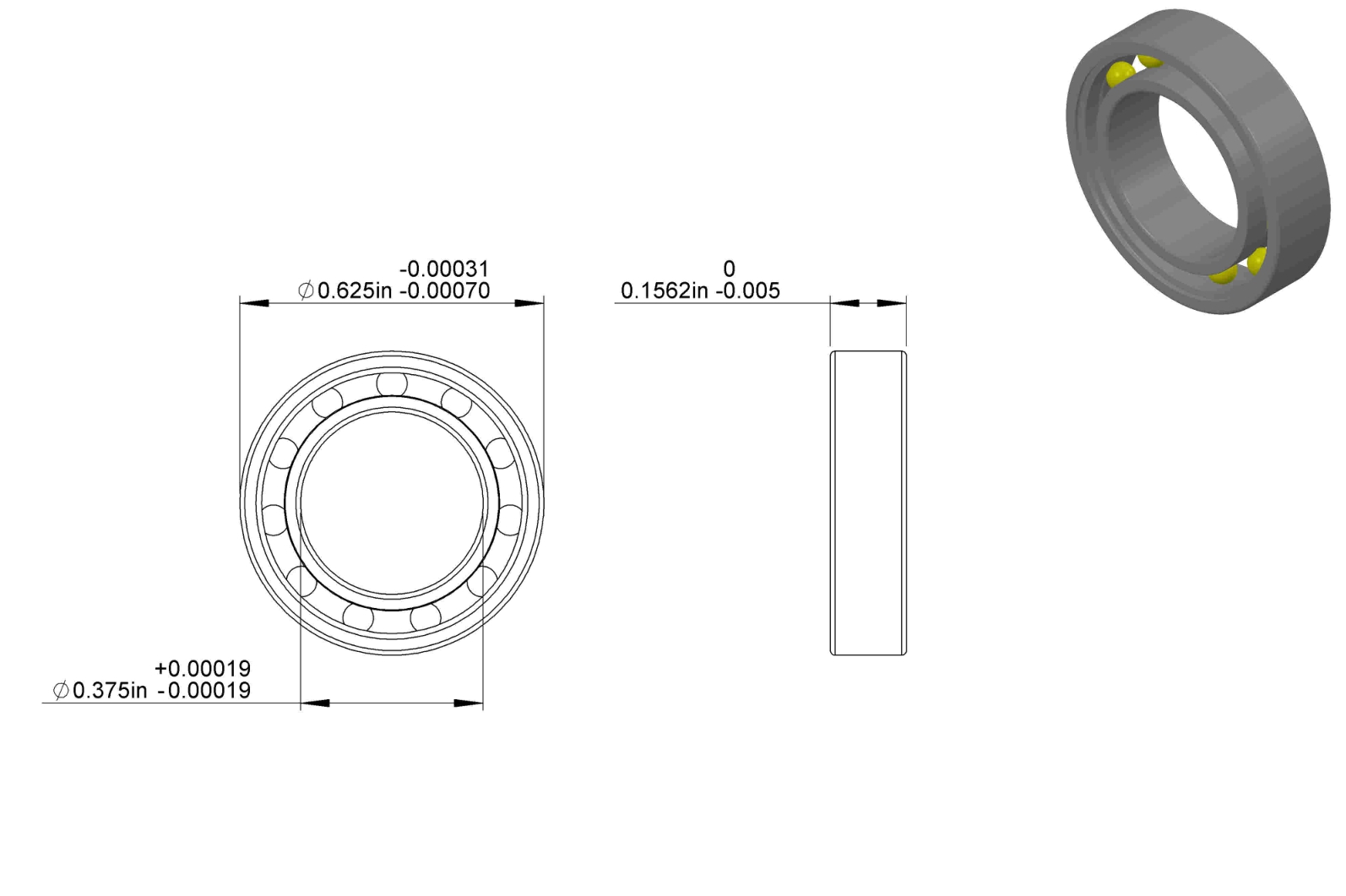

D/W ER1038 Bearing provides a robust and reliable bearing solution for applications requiring corrosion resistance and durability. D/W ER1038 bore dia is 0.375″. Its out dia is 0.625″. D/W ER1038 width is 0.15618″. Its structural advantages combined with the inherent benefits of deep groove ball bearings make it an invaluable component in a wide range of specialized applications.

What Benefits Can D/W ER1038 Bearing Provide?

- Corrosion Resistance: The stainless steel material provides excellent resistance against corrosive elements.

- High Load Capacities: Similar to standard deep groove ball bearings, they can handle both radial and axial loads.

- Low Friction: Despite their specialized material, they still offer low friction coefficients for high-speed operations.

- Extended Service Life: Due to their enhanced durability, these bearings generally have a longer service life, especially in corrosive environments.

What Can D/W ER1038 Bearing Be Used for?

D/W ER1038 Bearing is used for a wide range of applications, such as:

- Food & Beverage Industry: Often used in processing equipment that is frequently exposed to water and other liquids.

- Chemical Processing: Ideal for machinery exposed to aggressive chemicals.

- Marine Applications: Useful in environments with exposure to saltwater.

- Pharmaceuticals: Used in equipment that must adhere to strict hygiene and cleanliness standards.

- Medical Devices: In devices where non-corrosive properties are essential for long-term reliability.