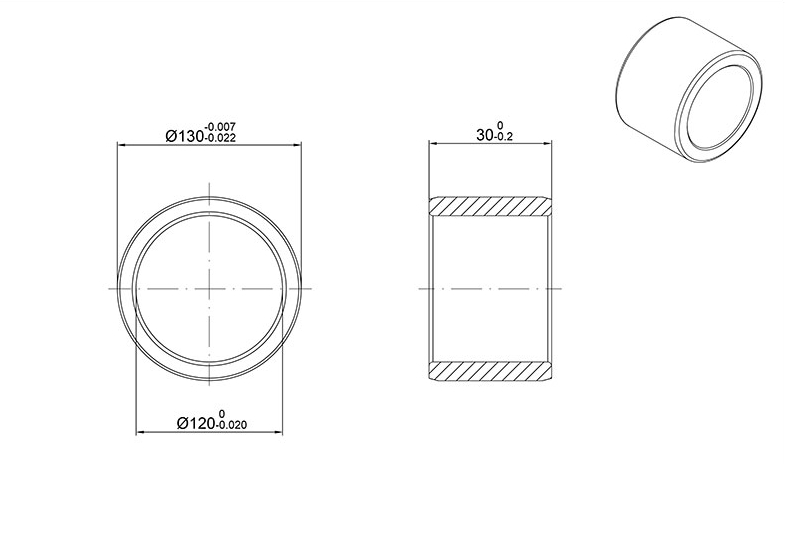

IR120X130X30-XL

Design Features of IR120X130X30-XL

IR120X130X30-XL is typically made from hardened steel and features a precision-ground surface to provide a smooth rolling path for bearing elements. IR120X130X30-XL outer dia is 130 mm. Its bore dia is 120 mm. Its cylindrical shape and tight tolerances ensure proper load distribution and efficient performance in various applications.

What Benefits Can IR120X130X30-XL Provide?

- Smooth Operation: Its precision-ground surface ensures low friction and smooth movement for rolling elements.

- Durability: Made from hardened steel, it offers excellent wear resistance and can handle heavy loads.

- Accurate Load Distribution: Its precise dimensions and tight tolerances help evenly distribute loads, enhancing bearing performance.

- Extended Service Life: By reducing wear and friction, the inner ring contributes to a longer lifespan of the overall bearing assembly.

- Versatility: It can be used in a wide range of applications and environments, including high-speed and high-load conditions.

What Can IR120X130X30-XL Be Used for?

- Bearings: It provides a rolling surface for the bearing elements in ball and roller bearings.

- Rotating Shafts: Used on rotating shafts to provide a durable surface for bearing elements and prevent wear on the shaft.

- Gearboxes: Ensures efficient operation in high-speed or high-load environments by supporting rolling elements in gear systems.

- Motors: Improves the smoothness and durability of motor assemblies by supporting the inner components.

- Pumps and Compressors: Helps handle radial and axial loads, reducing wear in high-speed industrial equipment.