| Part Number | N 1010 KPHA/HC5SP |

| Brand: BearingMaker | Interchangeable With: SKF |

| System of Measurement | Metric |

| Roller Bearing Type | Cylindrical |

| Bore Type | Taper 1:12 |

| For Load Direction | Combined |

| Construction | Single Row |

| Seal Type | Open |

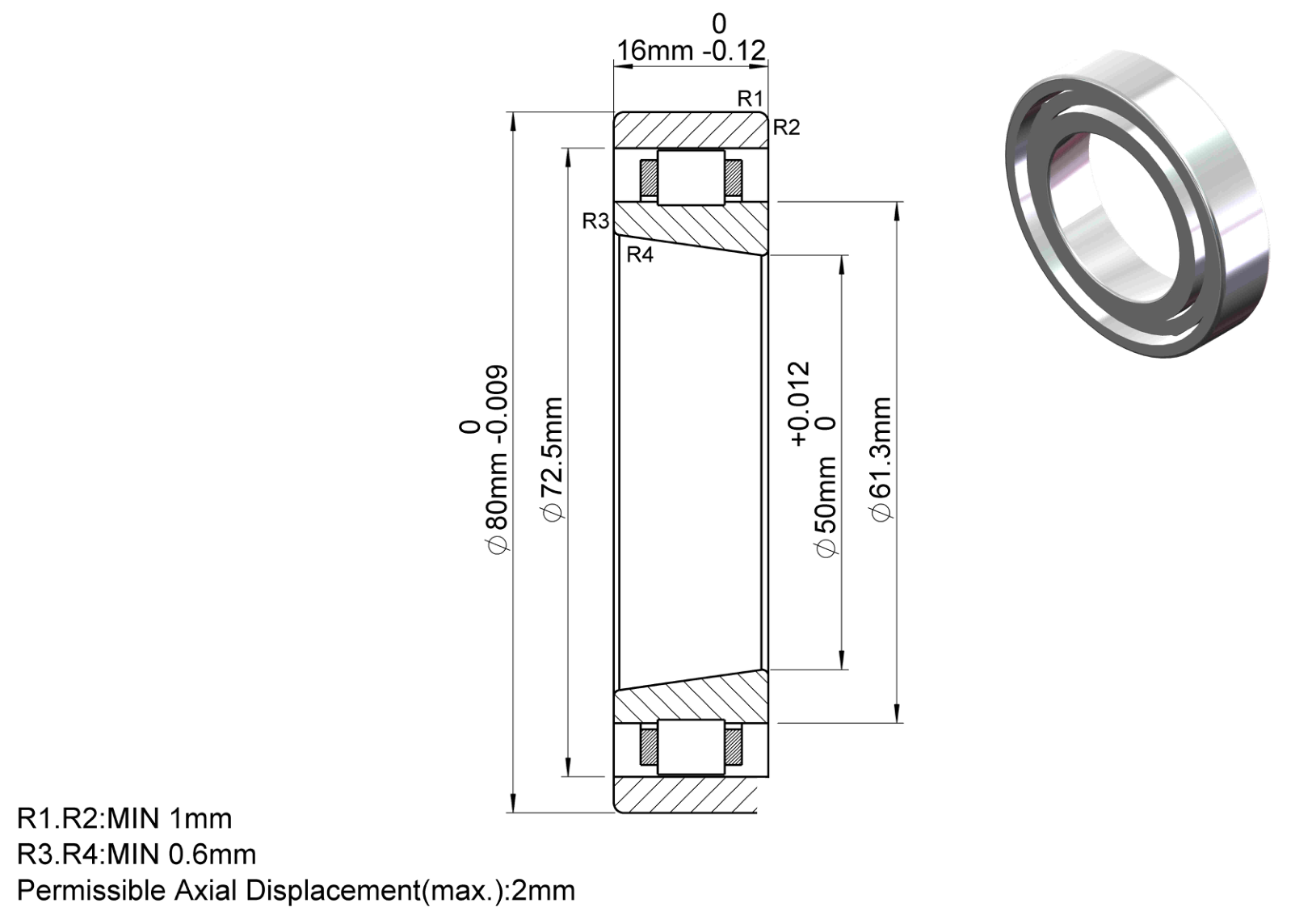

| Bore Dia | 50 mm |

| Bore Dia Tolerance | 0 to +0.012mm |

| Outer Dia | 80 mm |

| Outer Dia Tolerance | -0.010mm to 0 |

| Width | 16 mm |

| Width Tolerance | -0.12mm to 0 |

| Shoulder Dia Of Inner Ring | 61.3 mm |

| Raceway Diameter Outer Ring | 72.5 mm |

| Chamfer Dimension Outer Ring(r1,2)(min.) | 1 mm |

| Chamfer Dimension Inner Ring(r3,4)(min.) | 0.6 mm |

| Permissible Axial Displacement(max.) | 2 mm |

| Ring Material | Chrome Steel |

| Roller Material | Si3N4 |

| Cage Material | PEEK cage, outer ring centred |

| Dynamic Radial Load | 6435 lbf |

| Static Radial Load | 7538 lbf |

| Max Speed (X1000 rpm) | 32 |

| Lubrication | Grease, Oil |

| Temperature Range | -30° to 110 °C |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 0.22 kg |