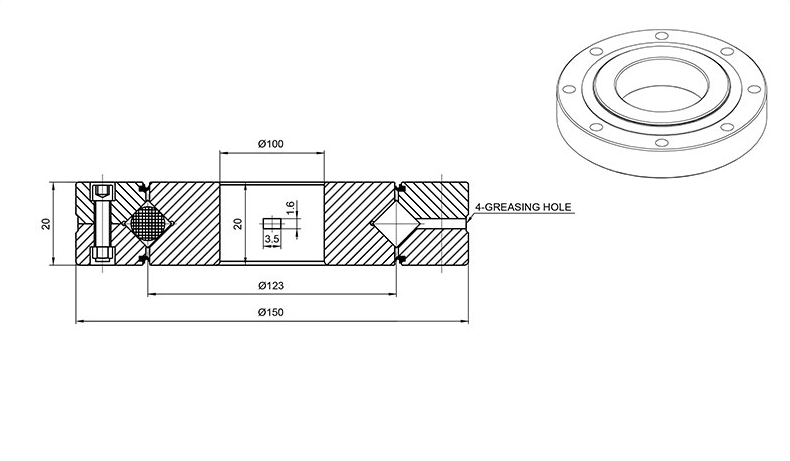

RB10020UU

Design Features of RB10020UU Bearing

RB10020UU Bearing is designed with a unique structure that allows for high rigidity and precision in applications with limited space. RB10020UU outer dia is 150 mm. Its bore dia is 100 mm. Its rollers are arranged in a crossed pattern, enabling it to support axial and radial loads simultaneously while minimizing friction and wear.

What Benefits Can RB10020UU Bearing Provide?

- High Load Capacity: Its design allows for the support of both axial and radial loads, making it suitable for applications with heavy load requirements.

- Compact Size: The crossed roller configuration enables a more compact design, ideal for applications with limited space.

- Enhanced Precision: The bearing provides high rotational accuracy and stability, making it suitable for precision machinery and equipment.

- Reduced Friction: The unique roller arrangement minimizes friction, leading to smoother operation and extended service life.

- Versatility: This bearing is adaptable for various applications, including robotics, machine tools, and industrial equipment.

- Improved Durability: The robust construction enhances durability and reliability, even in demanding conditions.

What Can RB10020UU Bearing Be Used for?

- Robotics: Ideal for robotic joints and axes due to their high precision and compact size.

- Machine Tools: Used in CNC machines and milling equipment for improved accuracy and stability.

- Industrial Equipment: Suitable for various types of industrial machinery requiring reliable load support and smooth operation.

- Medical Devices: Employed in surgical robots and imaging equipment for precise movements.

- Aerospace Applications: Utilized in systems where high reliability and performance are critical.

- Optical Equipment: Used in camera and lens mechanisms for precise positioning.

- Semiconductor Manufacturing: Essential in equipment requiring high precision and minimal wear during operation.