SF5C-ZZ AF2

Design Features of SF5C-ZZ AF2 Bearing

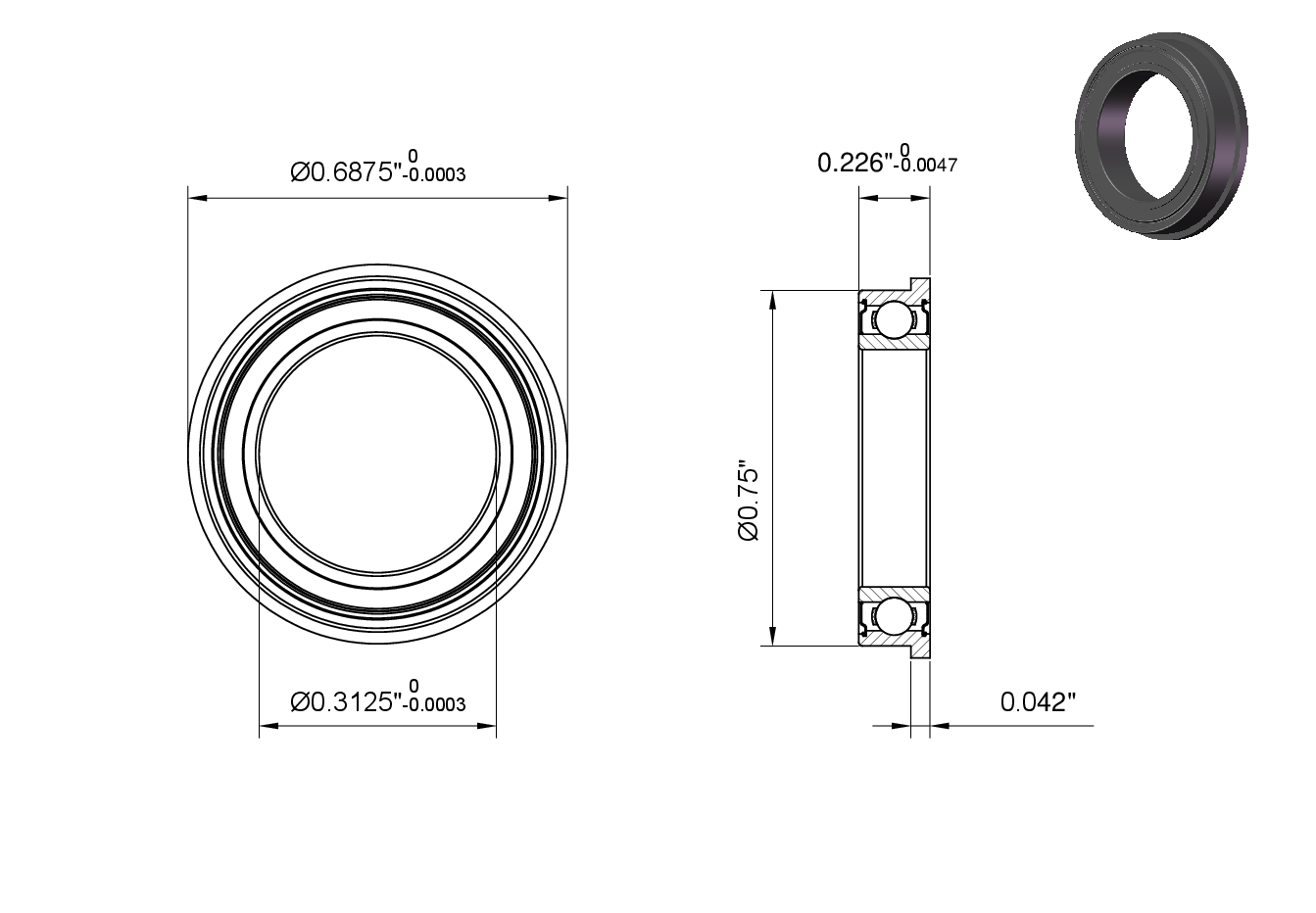

SF5C-ZZ AF2 Bearing seamlessly merges the distinct benefits of ceramic and steel components. The core of this bearing employs ceramic balls, housed within steel races. SF5C-ZZ AF2 bore dia is 0.3125″. Its out dia is 0.6875″. SF5C-ZZ AF2 width is 0.226″. The Flanged design further allows for easy positioning, leading to faster assembly and alignment, especially in applications where axial location is critical.

What Benefits Can SF5C-ZZ AF2 Bearing Provide?

- High-Speed Efficiency: Lighter ceramic elements enable faster operation with reduced centrifugal force.

- Enhanced Durability: Ceramic resists wear and handles high temperatures, extending service life.

- Reduced Friction: Ceramic balls reduce overall friction, lowering operational temperatures.

- Electrical Insulation: Prevents electrical arcing or current passage through the bearing.

- Corrosion Resistance: Ceramic’s inertness ensures resistance to corrosive environments.

- Precise Positioning: Flanged design allows for accurate axial location and stability, simplifying assembly processes.

What Can SF5C-ZZ AF2 Bearing Be Used for?

SF5C-ZZ AF2 Bearing is primarily used in applications requiring the combined benefits of ceramic and steel components, along with precise mounting capabilities. Its applications include:

- Electric Motors: It provides electrical insulation, preventing electrical erosion.

- High-Speed Machinery: Its low density and high hardness enable efficient high-speed operation.

- Precision Equipment: Used in CNC machines and precision instruments for enhanced accuracy and low friction.

- Automotive: Beneficial in high-performance and electric vehicles for efficiency and speed.

- Robotics: This bearing Offers precision, low friction, and durability, crucial for robotics.

- Pumps and Compressors: Improve efficiency and longevity due to reduced friction and wear resistance.

$9.15