Aerospace Spherical Bearings

Aerospace Spherical Bearings are specialized components engineered for flight-critical control systems in aircraft, spacecraft, and missiles. These bearings enable precise articulation, reduce maintenance needs through self-lubricating designs, and provide high load capacity under extreme conditions—making them vital for reliable aerospace performance.

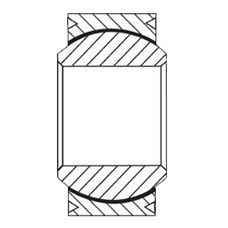

Introduction to Aerospace Spherical Bearings

Aerospace spherical bearings, also known as control rod end bearings or spherical plain bearings, are precision-engineered mechanical joints used to connect control rods, pushrods, and linkages in aircraft and aerospace systems. They are essential for enabling smooth rotational and oscillatory motion while transmitting loads between connected components. Their ability to absorb misalignment and maintain performance under stress makes them indispensable in control systems across airplanes, missiles, and spacecraft.

Construction and Materials

To perform reliably in extreme aerospace environments, aerospace spherical bearings are typically constructed from high-strength, corrosion-resistant materials. Common combinations include:

- Outer and inner rings: Made from stainless steel or high-strength alloy steel for load-bearing capacity and wear resistance.

- Raceway linings: Often lined with PTFE (Teflon) or other engineered polymers to provide self-lubricating properties and reduce maintenance requirements.

- Coatings: Surface treatments such as cadmium plating or zinc-nickel enhance corrosion resistance in harsh environments.

Key Design Features

The design of aerospace spherical bearings is tailored to meet the strict operational demands of aviation and aerospace systems. Key features include:

- Self-lubricating capability: Eliminates the need for frequent re-lubrication and ensures consistent performance over time.

- Misalignment compensation: Spherical geometry allows for angular misalignment without loss of performance.

- High static and dynamic load capacity: Supports both oscillatory and rotational movement under substantial forces.

- Compact design: Suitable for space-constrained installations, especially in flight control assemblies.

Types and Configurations

Spherical Bearings with Lined Races (Self-Lubricating)

These bearings feature a liner—commonly made of PTFE or similar polymers—between the inner and outer race. This design provides built-in lubrication, eliminating the need for external grease or oil. Self-lubricating spherical bearings are widely used in components where accessibility for maintenance is limited, such as:

- Flight control surfaces (e.g., rudders, elevators)

- Landing gear assemblies

- Engine mounts

Metal-to-Metal Bearings

Metal-to-metal spherical bearings do not have a polymer liner. Instead, they rely on high-precision surface finishes and robust materials to minimize wear. These are suitable for high-load, high-impact scenarios where longer service life is critical but lubrication is still periodically maintained.

Loader Slot Bearings

Loader slot spherical bearings are designed with a slot in the outer ring, allowing for easier installation into housings or assemblies. These are typically used in applications requiring field maintenance or quick replacement.

Rod End Bearings (Self-Lubricating & Metal-to-Metal)

Rod ends combine a spherical bearing with a threaded shaft, enabling attachment to control rods or linkages. These are commonly found in flight controls, actuation systems, and steering mechanisms in both fixed-wing and rotary-wing aircraft.

Sleeve Bearings (Self-Lubricating)

While not true spherical bearings, self-lubricating sleeve bearings are often used alongside spherical bearings in aerospace assemblies. They provide low-friction linear motion and are especially useful in pivot or slide applications.

The Importance of Aerospace Spherical Bearings

Spherical bearings serve as critical links in aerospace systems, directly influencing flight safety and mechanical reliability. Their importance lies in:

- Maintaining precise control: Allowing smooth and predictable motion in control systems.

- Handling extreme environments: Tolerating wide temperature ranges, vibration, and corrosion.

- Reducing maintenance: Especially through self-lubricating variants that operate without periodic servicing.

- Ensuring longevity: Designed to withstand repeated cycles of mechanical stress and motion over the aircraft’s operational life.

Compliance and Aerospace Standards

To ensure safety and interoperability, aerospace spherical bearings must comply with industry and manufacturer standards, such as:

- SAE-AS81820: Standard for self-aligning spherical bearings, self-lubricating type.

- SAE-AS81935: Specification for metal-to-metal bearings.

- Boeing and Airbus-specific specs: Custom requirements defined by OEMs for flight-critical applications.

Conclusion

Aerospace spherical bearings are foundational components in modern aircraft and spacecraft design, providing the articulation, reliability, and environmental resistance required in mission-critical systems. Whether in self-lubricating or metal-to-metal form, selecting the right bearing configuration is essential for safety, performance, and lifecycle cost optimization in aerospace engineering.

Showing 271–274 of 274 results