Aerospace Bearings

Aerospace Bearings are high-precision components engineered to meet the rigorous demands of aircraft and spacecraft systems. They ensure critical functions such as jet engine operation, landing gear support, and flight control responsiveness, all while maintaining reliability under extreme conditions.

What Are Aerospace Bearings?

Aerospace bearings are specialized components designed to ensure safe, reliable, and efficient performance in aviation and space applications. These bearings operate in systems exposed to extreme temperatures, high speeds, mechanical stress, and corrosive or vacuum environments. From jet propulsion to spaceflight hardware, aerospace bearings are vital for motion control and load management in critical applications.

Key Features of Aerospace Bearings

- High Precision and Reliability: Manufactured with ultra-tight tolerances to ensure accurate movement in systems such as flight controls and turbines.

- Lightweight Design: Constructed using advanced materials like titanium and ceramics to reduce weight and improve fuel efficiency.

- High Load Capacity: Capable of handling both dynamic and static loads in high-performance aviation systems.

- Durability in Harsh Conditions: Engineered for environments with extreme temperature variations, aggressive chemicals, pressure changes, and radiation exposure.

- Low Torque Performance: Designed for frictionless operation to minimize energy loss and optimize responsiveness.

Types of Aerospace Bearings

Several types of bearings are used in aerospace systems, each serving a specific function based on design and performance needs:

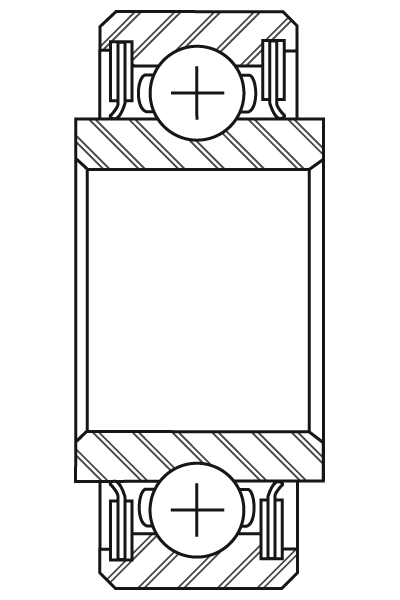

Airframe Control Ball Bearings

These bearings support flight control components like slats, flaps, and actuator assemblies. They offer high corrosion resistance, precision movement, and the ability to handle fluctuating loads during various phases of flight.

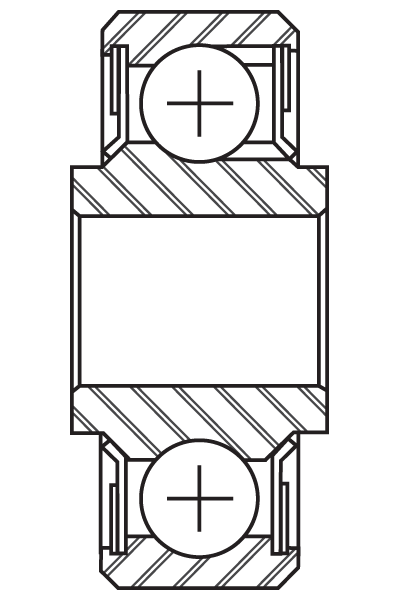

Aerospace Spherical Bearings

Spherical bearings are ideal for applications requiring angular misalignment compensation, such as landing gear or actuator joints. They are built for strength, durability, and performance in high-load, high-impact environments with minimal maintenance.

Common Materials Used in Aerospace Bearings

Aerospace bearings are manufactured using advanced materials selected for their ability to withstand the industry’s harshest operating conditions:

- Stainless Steel: Excellent corrosion resistance in humid or chemically exposed environments.

- Chrome Steel: Offers high hardness and wear resistance for high-stress applications like gearboxes.

- Silicon Nitride Ceramic: Lightweight, low-friction, and stable at high speeds and variable temperatures.

- Titanium Alloys: High strength-to-weight ratio and thermal resistance, ideal for aerospace structures and engines.

- M50 Steel: Extreme heat resistance, often used in jet engines and aerospace turbines.

- Ceramic Hybrid Bearings: Combine ceramic balls with steel races for improved performance, lower weight, and reduced thermal expansion.

Critical Applications of Aerospace Bearings

Aerospace bearings are integral to various mission-critical systems in both aviation and space technology:

Jet Engines

Bearings in jet engines support main shafts, turbines, and compressors. They must withstand extreme temperatures, centrifugal forces, and high-speed rotations for sustained, reliable operation.

Landing Gear Systems

These bearings endure significant shock and stress during takeoff, landing, and taxiing. They are engineered for impact resistance, durability, and corrosion protection under load-heavy conditions.

Flight Control Systems

Flight control bearings enable precise movement of control surfaces such as flaps, rudders, and elevators. Their low-friction design ensures responsiveness and control during high-speed maneuvering.

Spacecraft Components

In space environments, aerospace bearings must operate in vacuums, endure radiation, and manage extreme thermal fluctuations. Applications include satellite positioning mechanisms, robotic arms, and solar array actuators, where reliability is critical due to lack of maintenance opportunities.

Conclusion

Aerospace bearings are essential components in aviation and spaceflight systems where safety, precision, and performance are non-negotiable. Their advanced materials, high load capacities, and ability to function in extreme environments make them a preferred choice for OEMs and aerospace engineers. For optimal results, it is important to choose the right bearing type and material based on specific operational conditions. Consult with a bearing specialist for guidance on aerospace-grade solutions tailored to your project.

Showing 511–517 of 517 results