7220 CDGA/HCP4A

Design Features of 7220 CDGA/HCP4A Bearing

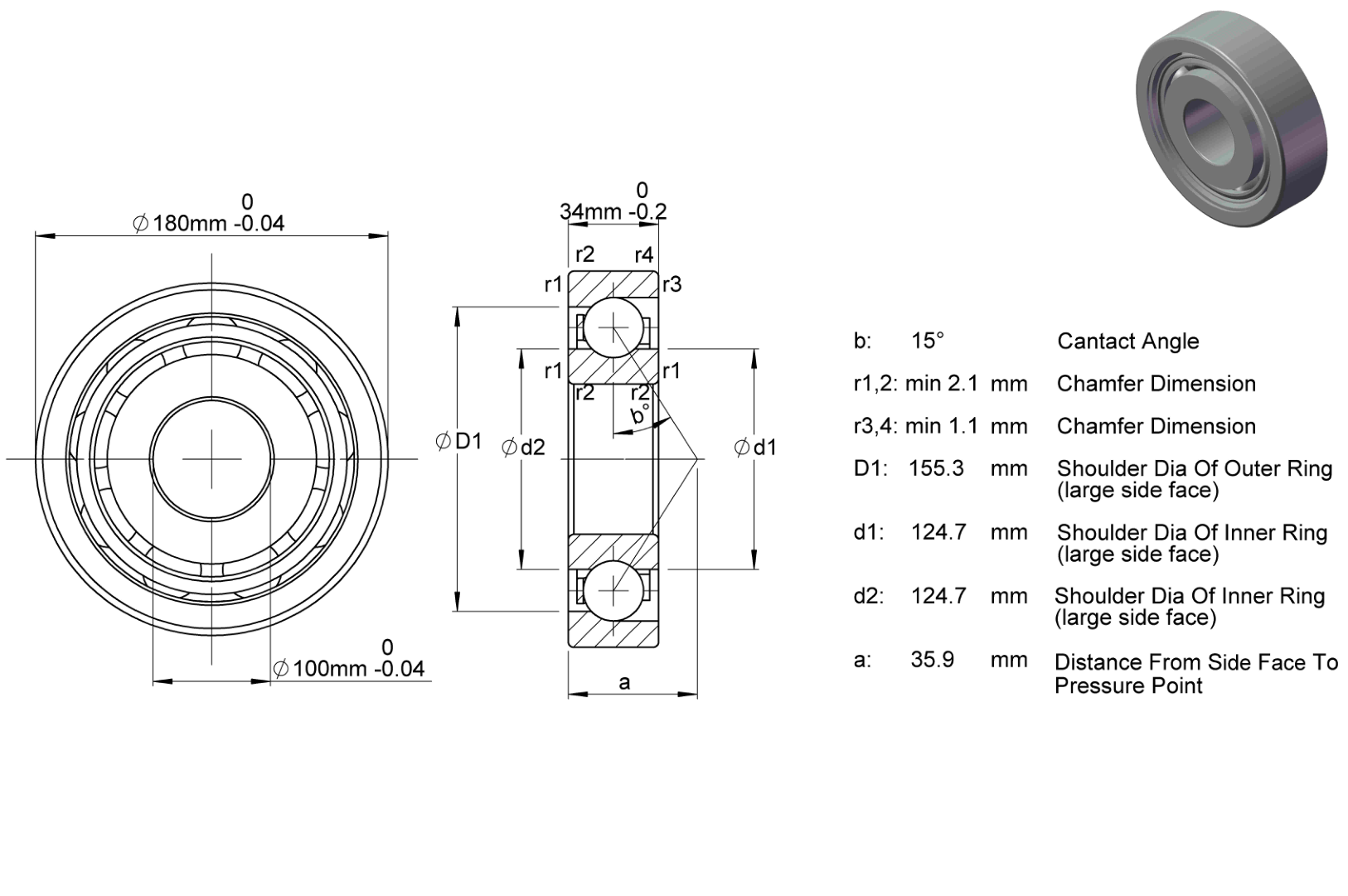

The design of 7220 CDGA/HCP4A Bearing is a culmination of advanced materials science, mechanical engineering, and precision manufacturing. 7220 CDGA/HCP4A bore dia is 100 mm. Its out dia is 180 mm. 7220 CDGA/HCP4A width is 34 mm. This bearing is integral in high-speed spindles, precision instruments, and applications where accuracy and speed are critical.

What Benefits Can 7220 CDGA/HCP4A Bearing Provide?

- High-Speed Capabilities: Optimized for high rotational speeds with minimal friction and heat generation.

- Exceptional Precision: Manufactured to ultra-precise tolerances, ensuring unparalleled accuracy in operation.

- Enhanced Rigidity and Stability: Offer superior axial and radial rigidity, maintaining stability under varying load conditions.

- Advanced Material Use: Constructed from high-grade materials for durability, wear resistance, and performance at high speeds and temperatures.

- Low Friction and Heat Dissipation: Designed to minimize internal friction, efficiently dissipating heat to prolong bearing life.

What Can 7220 CDGA/HCP4A Bearing Be Used for?

7220 CDGA/HCP4A Bearing is used in applications where high precision, speed, and reliability are paramount. Their typical uses include:

- Machine Tool Spindles: Essential in CNC machines and precision grinders, where they ensure high-speed, accurate tool performance.

- High-Speed Machinery: Used in equipment requiring high rotational speeds, such as drilling and milling machines.

- Aerospace Components: Crucial in aerospace applications for gyroscopes, actuators, and jet engine components due to their precision and stability.

- Medical Equipment: Employed in high-speed medical devices like dental drills and medical imaging equipment.

- Semiconductor Manufacturing: Used in semiconductor production equipment where precision and speed are crucial for accurate wafer processing.