Airframe Control Ball Bearings

Airframe Control Ball Bearings are specialized aerospace components designed for lightweight, corrosion-resistant, and low-maintenance performance in demanding applications such as flight control systems, landing gear, and engine mounts. Their precision and reliability make them essential in maintaining aircraft safety and maneuverability.

What Are Airframe Control Ball Bearings?

Airframe control ball bearings are high-precision components used in critical aircraft subsystems. Typically constructed from corrosion-resistant materials like stainless steel, they are sealed and grease-lubricated for long-lasting, low-maintenance performance. These bearings are specifically designed for oscillating and heavy-duty movements common in flight environments, offering smooth, reliable motion while minimizing friction under dynamic loads.

Key Features of Airframe Control Bearings

- Lightweight Construction: Engineered from advanced alloys to minimize aircraft weight.

- Corrosion Resistance: Surfaces are protected with treatments such as cadmium or zinc-nickel plating.

- Sealed and Grease-Lubricated: Designed for long service life with minimal maintenance.

- High Durability: Withstands harsh environments including extreme temperatures, vibration, and pressure.

Types of Airframe Control Ball Bearings

Airframe control bearings are available in over 27 standardized subcategories, with variations in design to meet different performance demands. Here are the most common types:

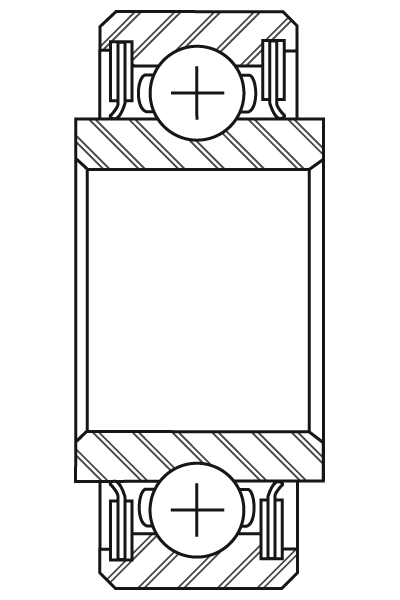

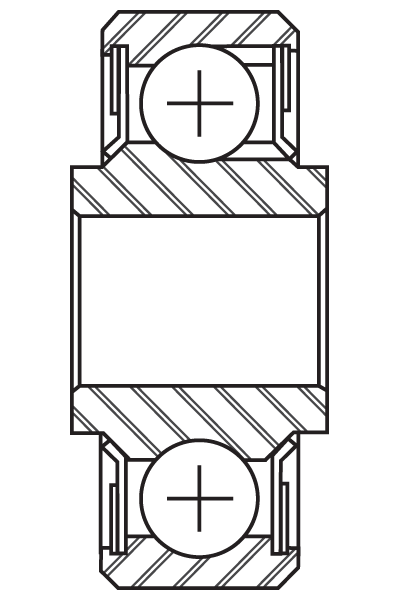

Ball Bearings

Single-row and double-row ball bearings are used in applications requiring low friction and high-speed rotation. These bearings are ideal for deep groove, angular contact, and self-aligning setups within aircraft systems.

Roller Bearings

Roller bearings, such as cylindrical and tapered styles, are suitable for high radial load capacities. They are often found in high-stress and heavy-duty airframe components.

Swivel (Spherical Plain) Bearings

These bearings allow for angular misalignment, making them perfect for flight control surfaces that experience non-linear motion. They ensure consistent operation even under high-stress directional changes.

Common Applications of Airframe Control Bearings

These bearings play a pivotal role in multiple aircraft subsystems where precision, strength, and reliability are critical.

Flight Control Systems

Used in systems like ailerons, rudders, elevators, and rotor actuators, these bearings ensure accurate and responsive control throughout various flight maneuvers.

Landing Gear

Heavy-duty variants are employed in landing gear assemblies, where they absorb high loads during takeoff, landing, and taxiing operations.

Engine Mounts

Specialized airframe bearings help isolate engine vibrations while accommodating thermal expansion and contraction, improving performance and durability in extreme conditions.

Advantages of Airframe Control Ball Bearings

- Reliable performance under dynamic and static loads

- High precision for accurate flight control response

- Resistance to corrosion, high temperatures, and harsh environments

- Low maintenance with sealed, grease-lubricated designs

- Extended service life in demanding aerospace applications

How to Choose the Right Airframe Control Bearings

Selecting the appropriate bearing involves analyzing both performance and environmental requirements:

- Radial and thrust load capacities

- Motion type: oscillating, rotational, or combined

- Operating conditions: temperature, pressure, and contaminants

- Size and weight constraints (including thin-section designs)

- Lubrication needs: standard grease or PTFE-lined self-lubricating bearings

- Compliance with industry standards (e.g., SAE-AS7949, Boeing specs)

Industry Standards and Certifications

Airframe control bearings must meet strict aerospace regulations to ensure safety and interoperability. These include:

- SAE-AS7949: Aerospace standard governing performance and testing requirements for airframe control bearings.

- Boeing Specifications: Mandatory requirements for bearings used in Boeing-manufactured aircraft.

- General Aerospace Standards: Cover quality, durability, and dimensional accuracy benchmarks.

Maintenance and Troubleshooting Tips

Though designed for minimal upkeep, proper maintenance extends bearing life and prevents operational issues:

- Adhere to manufacturer-recommended lubrication intervals

- Inspect regularly for wear, corrosion, or noise/vibration anomalies

- Ensure correct alignment during installation

- Replace bearings based on usage cycles or if damage is detected

Conclusion

Airframe control ball bearings are indispensable components in modern aircraft, offering the reliability, precision, and performance required in flight-critical systems. Their ability to endure extreme conditions with minimal maintenance makes them the preferred choice for engineers and procurement teams in the aerospace sector. Selecting the right bearing type, material, and certification is essential to ensure safe and efficient aircraft operation.

Showing 241–243 of 243 results